Revolutionizing Energy Storage: How High-Performance Battery Cooling Will Shape 2025 and Beyond. Explore the Breakthroughs, Market Surge, and Future-Ready Solutions Powering the Next Era of Electrification.

- Executive Summary: Key Trends and Market Drivers in 2025

- Market Size & Growth Forecast (2025–2030): CAGR, Revenue, and Volume Analysis

- Technology Landscape: Liquid, Air, and Advanced Phase-Change Cooling Solutions

- Automotive Sector: EV Battery Cooling Innovations and OEM Strategies

- Industrial & Grid Storage: Scaling High-Performance Cooling for Large-Format Batteries

- Key Players & Strategic Partnerships: Leading Manufacturers and Collaborations

- Regulatory Standards and Safety Requirements: Global Compliance Overview

- R&D Pipeline: Next-Generation Materials and Smart Thermal Management

- Regional Analysis: North America, Europe, Asia-Pacific, and Emerging Markets

- Future Outlook: Disruptive Trends, Investment Hotspots, and Long-Term Opportunities

- Sources & References

Executive Summary: Key Trends and Market Drivers in 2025

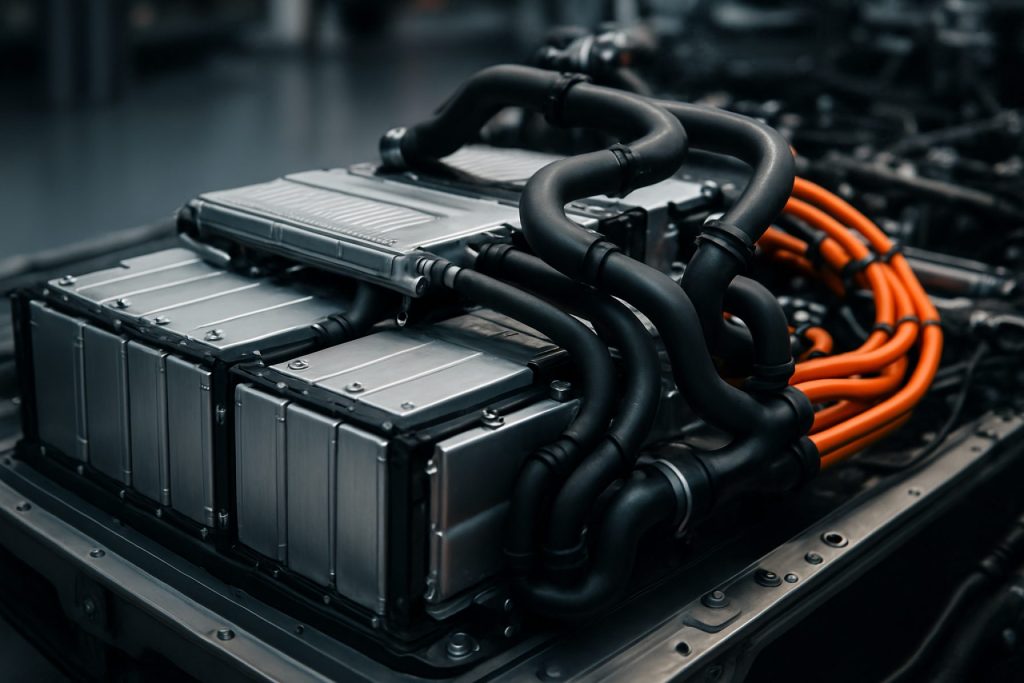

The high-performance battery cooling sector is experiencing rapid evolution in 2025, driven by the accelerating adoption of electric vehicles (EVs), energy storage systems, and the increasing demands for safety, efficiency, and longevity in battery technologies. As battery energy densities rise and fast-charging becomes mainstream, effective thermal management has become a critical differentiator for manufacturers and end-users alike.

A key trend in 2025 is the widespread shift from traditional air-cooling systems to advanced liquid cooling and immersion cooling solutions. Leading automotive OEMs and battery manufacturers are investing heavily in these technologies to address the thermal challenges posed by high-capacity lithium-ion and emerging solid-state batteries. For instance, LG Energy Solution and Panasonic Corporation are both integrating sophisticated liquid cooling modules into their latest battery packs, aiming to support ultra-fast charging and extend battery life cycles. Similarly, Tesla, Inc. continues to refine its proprietary cooling manifolds and glycol-based systems, which are now standard in its high-performance vehicles and stationary storage products.

Thermal runaway prevention and regulatory compliance are also shaping the market. The introduction of stricter safety standards by organizations such as the SAE International and the International Organization for Standardization (ISO) is compelling manufacturers to adopt more robust cooling architectures. Battery cooling system suppliers like Dana Incorporated and MAHLE GmbH are responding with modular, scalable solutions that can be tailored to diverse vehicle platforms and grid-scale storage applications.

Another significant driver is the push for sustainability and energy efficiency. Companies are developing recyclable coolants and low-carbon manufacturing processes to align with global decarbonization goals. Valeo, for example, is advancing eco-friendly thermal management fluids and compact heat exchangers designed to minimize environmental impact while maximizing performance.

Looking ahead, the market outlook for high-performance battery cooling remains robust. The proliferation of gigafactories, the expansion of EV charging infrastructure, and the anticipated commercialization of next-generation battery chemistries will continue to fuel demand for innovative cooling solutions. Industry leaders are expected to prioritize R&D investments, strategic partnerships, and vertical integration to secure competitive advantages in this rapidly evolving landscape.

Market Size & Growth Forecast (2025–2030): CAGR, Revenue, and Volume Analysis

The high-performance battery cooling market is poised for robust expansion between 2025 and 2030, driven by the accelerating adoption of electric vehicles (EVs), energy storage systems, and advancements in battery chemistries that demand precise thermal management. As battery energy densities increase and fast-charging becomes more prevalent, the need for advanced cooling solutions—such as liquid cooling, immersion cooling, and phase-change materials—has intensified across automotive, industrial, and grid applications.

In 2025, the global market for high-performance battery cooling systems is estimated to reach a value in the low-to-mid single-digit billion USD range, with projections indicating a compound annual growth rate (CAGR) of approximately 15–20% through 2030. This growth is underpinned by the rapid scale-up of EV production, with leading automakers such as Tesla, Inc., BMW Group, and Mercedes-Benz Group AG integrating advanced liquid cooling modules into their latest battery packs to support higher power densities and faster charging cycles.

Volume-wise, the number of high-performance battery cooling units shipped is expected to parallel the surge in EV and stationary storage deployments. For instance, LG Energy Solution and Panasonic Holdings Corporation—both major battery cell suppliers—are scaling up production of battery modules that require sophisticated cooling architectures, particularly for next-generation lithium-ion and solid-state batteries. The stationary energy storage sector, led by companies like Siemens AG and Hitachi Energy, is also contributing to demand, as grid-scale systems increasingly rely on high-capacity batteries with stringent thermal management needs.

The Asia-Pacific region is anticipated to dominate both revenue and volume, reflecting the concentration of battery manufacturing and EV assembly in China, South Korea, and Japan. European and North American markets are also set for significant growth, spurred by regulatory mandates for zero-emission vehicles and investments in local battery gigafactories. Key suppliers of battery cooling technologies, such as DENSO Corporation, Mahindra CIE Automotive Ltd., and Modine Manufacturing Company, are expanding their portfolios to address the evolving requirements of OEMs and energy storage integrators.

Looking ahead, the market outlook remains highly positive, with innovation in cooling fluids, compact heat exchangers, and integrated thermal management systems expected to further accelerate adoption. As battery performance and safety standards tighten, high-performance cooling will remain a critical enabler of electrification across mobility and energy sectors through 2030.

Technology Landscape: Liquid, Air, and Advanced Phase-Change Cooling Solutions

The technology landscape for high-performance battery cooling in 2025 is characterized by rapid innovation, driven by the increasing energy density of batteries and the growing demand for electric vehicles (EVs), grid storage, and high-power electronics. Three primary cooling approaches—liquid, air, and advanced phase-change solutions—are shaping the sector, each with distinct advantages and deployment trends.

Liquid cooling remains the dominant technology for high-performance battery systems, especially in EVs and stationary storage. This method uses water-glycol or dielectric fluids circulated through channels or plates adjacent to battery cells, offering superior heat transfer and temperature uniformity. Leading automotive manufacturers such as Tesla and BMW have standardized liquid cooling in their latest EV platforms, citing its ability to support fast charging and extend battery life. In 2024, LG Energy Solution and Panasonic both announced next-generation battery modules with integrated liquid cooling, targeting higher power densities and improved safety. The trend is expected to continue through 2025, with further integration of smart thermal management systems and predictive controls.

Air cooling remains relevant for lower-cost or lower-power applications, such as hybrid vehicles, two-wheelers, and some stationary storage systems. While less efficient than liquid cooling, air-based systems are simpler, lighter, and easier to maintain. Companies like Nissan and Hyundai Motor Company continue to deploy advanced air cooling in select models, leveraging improved airflow designs and variable-speed fans. However, as battery capacities and charging rates increase, the limitations of air cooling are becoming more apparent, and its share in high-performance segments is expected to decline.

Advanced phase-change materials (PCMs) and two-phase cooling solutions are emerging as next-generation options for ultra-high-performance and safety-critical applications. PCMs absorb and release large amounts of heat during phase transitions, providing passive thermal buffering during peak loads. Companies such as Saft (a subsidiary of TotalEnergies) and Samsung SDI are actively developing PCM-enhanced modules for aerospace, defense, and high-power grid storage. Meanwhile, two-phase immersion cooling—where batteries are submerged in dielectric fluids that vaporize and condense to transfer heat—has attracted interest from data center and specialty vehicle sectors. 3M and Shell are investing in new dielectric fluids and system integration, with pilot deployments expected to expand in 2025 and beyond.

Looking ahead, the convergence of liquid cooling with smart sensors, the maturation of PCM and two-phase technologies, and the push for higher charging rates are set to redefine the high-performance battery cooling landscape. Industry leaders are prioritizing modular, scalable, and energy-efficient solutions to meet the evolving demands of electrification across sectors.

Automotive Sector: EV Battery Cooling Innovations and OEM Strategies

The rapid acceleration of electric vehicle (EV) adoption in 2025 is driving unprecedented innovation in high-performance battery cooling systems. As automakers push for higher energy densities, faster charging, and longer lifespans, thermal management has become a critical differentiator in the automotive sector. Leading original equipment manufacturers (OEMs) and suppliers are investing heavily in advanced cooling technologies to address the challenges posed by next-generation lithium-ion and emerging solid-state batteries.

One of the most significant trends is the shift from traditional air cooling to sophisticated liquid cooling architectures. Liquid cooling offers superior heat dissipation, enabling batteries to operate safely at higher power outputs and during rapid charging cycles. For example, Tesla, Inc. continues to refine its integrated liquid-cooled battery modules, which are central to the performance of its Model S Plaid and Cybertruck platforms. These systems use precisely engineered coolant channels and thermal interface materials to maintain optimal cell temperatures, even under extreme load conditions.

European OEMs are also at the forefront of battery cooling innovation. Bayerische Motoren Werke AG (BMW) has introduced modular battery packs with dedicated liquid cooling plates, supporting both high-performance M-series EVs and mainstream models. Similarly, Volkswagen AG employs scalable cooling solutions across its MEB platform, ensuring consistent thermal management from compact cars to SUVs. These strategies are crucial for supporting ultra-fast charging—often exceeding 200 kW—without compromising battery health or safety.

Asian manufacturers are leveraging their expertise in battery technology to develop integrated cooling and battery management systems. LG Energy Solution and Panasonic Corporation are supplying advanced battery modules with embedded cooling channels to global OEMs, while BYD Company Limited has implemented its proprietary “Blade Battery” design, which features direct cooling contact for enhanced thermal stability and safety.

Looking ahead, the next few years will see the commercialization of immersion cooling, where battery cells are submerged in dielectric fluids for uniform heat removal. Companies like Robert Bosch GmbH are actively developing such systems, aiming to support the demands of high-performance EVs and commercial vehicles. Additionally, the integration of predictive thermal management—using real-time data and AI algorithms—will enable dynamic cooling adjustments, further optimizing battery performance and longevity.

As regulatory pressures for safety and efficiency intensify, and as consumer expectations for range and charging speed rise, high-performance battery cooling will remain a focal point of automotive R&D. The collaborative efforts of OEMs, battery suppliers, and technology firms are set to deliver increasingly robust and scalable solutions, shaping the competitive landscape of electric mobility through 2025 and beyond.

Industrial & Grid Storage: Scaling High-Performance Cooling for Large-Format Batteries

The rapid expansion of industrial and grid-scale energy storage is intensifying the demand for high-performance battery cooling solutions, particularly as installations increasingly rely on large-format lithium-ion and emerging chemistries. In 2025, global grid battery deployments are projected to surpass 100 GWh annually, with utility-scale projects often exceeding 100 MWh per site. This scale amplifies thermal management challenges, as even minor temperature gradients can degrade cell life, reduce efficiency, and pose safety risks.

Leading battery system integrators and manufacturers are prioritizing advanced liquid cooling architectures over traditional air cooling, due to superior heat transfer and tighter temperature control. Contemporary Amperex Technology Co., Limited (CATL), the world’s largest battery producer, has implemented integrated liquid cooling plates in its EnerC and EnerOne containerized storage systems, enabling uniform cell temperatures and supporting higher C-rates for fast response applications. Similarly, LG Energy Solution and Samsung SDI are deploying modular liquid-cooled racks in their grid storage offerings, citing improved cycle life and safety margins.

Thermal management suppliers are scaling up to meet these requirements. Danfoss and Bosch have expanded their portfolios to include high-capacity chillers, heat exchangers, and smart pump systems tailored for megawatt-scale battery enclosures. These systems often integrate with battery management systems (BMS) to dynamically adjust cooling based on real-time cell data, optimizing energy use and extending asset life. Saft, a subsidiary of TotalEnergies, has highlighted the role of predictive cooling algorithms in its Intensium Max grid storage platform, which leverages liquid cooling to maintain cell temperatures within a narrow band, even during rapid charge/discharge cycles.

Looking ahead, the next few years will see further innovation as solid-state and sodium-ion batteries enter the grid market, each with distinct thermal profiles. Companies such as Natrium (a joint venture between TerraPower and PacifiCorp) are developing sodium-based systems that, while less flammable, still require precise cooling to ensure longevity and performance. Meanwhile, the integration of waste heat recovery and hybrid cooling (combining liquid and phase-change materials) is under active development, aiming to boost round-trip efficiency and reduce operational costs.

As grid storage scales, high-performance cooling will remain a critical enabler for safety, reliability, and economic viability, with industry leaders investing heavily in both hardware and intelligent control to meet the sector’s evolving demands.

Key Players & Strategic Partnerships: Leading Manufacturers and Collaborations

The high-performance battery cooling sector is witnessing rapid evolution as electric vehicle (EV) adoption accelerates and energy storage systems demand greater efficiency and safety. In 2025 and the coming years, leading manufacturers and strategic partnerships are shaping the landscape, focusing on advanced thermal management solutions to support next-generation batteries.

Among the most prominent players, LG Energy Solution stands out as a global leader in battery technology, actively developing integrated cooling systems for its lithium-ion battery packs used in EVs and stationary storage. Samsung SDI is similarly investing in high-performance cooling, collaborating with automotive OEMs to deliver compact, efficient thermal management modules for high-density battery applications.

Automotive giants are also at the forefront. Tesla, Inc. continues to refine its proprietary liquid cooling architecture, which is central to the performance and longevity of its battery packs. The company’s Gigafactories are increasingly focused on in-house development of advanced cooling plates and manifolds, aiming to optimize cell temperature uniformity and enable faster charging cycles.

European manufacturers are making significant strides as well. Robert Bosch GmbH is a key supplier of battery thermal management systems, providing modular solutions for both passenger and commercial EVs. Bosch’s recent partnerships with automakers and battery producers are expected to yield new cooling technologies tailored for solid-state and high-capacity lithium-ion cells.

In the supplier ecosystem, DENSO Corporation and Mahindra Thermal Systems (a division of Mahindra Group) are expanding their portfolios with compact, high-efficiency heat exchangers and coolant distribution units. DENSO, in particular, is leveraging its expertise in automotive HVAC to deliver integrated battery and cabin cooling solutions, while Mahindra Thermal Systems is targeting the fast-growing Indian and Southeast Asian EV markets.

Strategic collaborations are accelerating innovation. For example, LG Energy Solution and Honda Motor Co., Ltd. have announced joint ventures to co-develop battery modules with advanced cooling for upcoming EV platforms. Similarly, Panasonic Corporation is working closely with automakers to integrate its proprietary cooling technologies into prismatic and cylindrical cell formats.

Looking ahead, the sector is expected to see further consolidation and cross-industry partnerships, as battery manufacturers, automotive OEMs, and thermal management specialists align to meet the demands of ultra-fast charging, higher energy densities, and stringent safety standards. The next few years will likely bring a wave of new product launches and pilot projects, cementing the role of collaborative innovation in high-performance battery cooling.

Regulatory Standards and Safety Requirements: Global Compliance Overview

The rapid evolution of high-performance battery cooling systems, particularly for electric vehicles (EVs) and energy storage, is closely intertwined with increasingly stringent regulatory standards and safety requirements worldwide. As of 2025, global compliance frameworks are being shaped by both established and emerging regulations, with a strong focus on thermal management to prevent battery overheating, thermal runaway, and associated hazards.

In the European Union, the United Nations Economic Commission for Europe (UNECE) Regulation No. 100 (R100) sets out comprehensive requirements for the safety of rechargeable energy storage systems, including provisions for thermal management and battery cooling. The regulation mandates that battery systems must be designed to prevent overheating and ensure safe operation under both normal and fault conditions. The EU’s General Safety Regulation (GSR) further reinforces these requirements, with updates effective from July 2024, mandating advanced safety features for new vehicles, including those related to battery integrity and thermal event mitigation (UNECE).

In the United States, the National Highway Traffic Safety Administration (NHTSA) and the Society of Automotive Engineers (SAE) have established standards such as FMVSS 305 and SAE J2929, which address electric vehicle battery safety, including thermal management and cooling system performance. The U.S. Department of Energy (DOE) also funds research and sets guidelines for battery safety and cooling technologies, aiming to reduce the risk of thermal events and improve system reliability (NHTSA, U.S. Department of Energy).

China, the world’s largest EV market, enforces the GB 38031-2020 standard, which stipulates rigorous requirements for battery thermal management, including real-time temperature monitoring and active cooling systems to prevent thermal runaway. The China Automotive Technology and Research Center (CATARC) plays a key role in testing and certifying compliance with these standards (China Automotive Technology and Research Center).

Japan and South Korea, home to major battery and automotive manufacturers, have adopted similar frameworks, with the Japan Automobile Standards Internationalization Center (JASIC) and the Korea Automobile Testing & Research Institute (KATRI) overseeing compliance and certification for battery cooling and safety systems (Japan Automobile Standards Internationalization Center, Korea Automobile Testing & Research Institute).

Looking ahead, regulatory bodies are expected to further tighten requirements for high-performance battery cooling, driven by the proliferation of fast-charging infrastructure, higher energy density batteries, and the need for robust safety assurances. Manufacturers such as LG Energy Solution, Panasonic, and Samsung SDI are actively collaborating with regulators to ensure their cooling technologies meet or exceed evolving global standards, positioning themselves for compliance and market leadership in the coming years.

R&D Pipeline: Next-Generation Materials and Smart Thermal Management

The rapid evolution of electric vehicles (EVs) and grid-scale energy storage is intensifying the demand for high-performance battery cooling solutions. As battery energy densities increase and fast-charging becomes mainstream, thermal management is a critical R&D focus for 2025 and the coming years. Next-generation materials and smart thermal management systems are at the forefront of this innovation pipeline, with leading battery manufacturers, automotive OEMs, and material science companies investing heavily in advanced cooling technologies.

One major trend is the shift from traditional air and liquid cooling to more sophisticated approaches such as immersion cooling and phase-change materials (PCMs). Immersion cooling, where battery cells are directly submerged in dielectric fluids, is being actively developed by companies like Saft (a subsidiary of TotalEnergies), which is piloting systems for both stationary and mobile applications. This method offers superior heat dissipation and uniform temperature control, which is crucial for high-power applications and fast-charging scenarios.

Material innovation is another key area. Companies such as BASF are developing advanced thermal interface materials (TIMs) and high-performance polymers that enhance heat transfer between battery cells and cooling plates. These materials are designed to withstand the mechanical and chemical stresses of repeated charge-discharge cycles, while maintaining high thermal conductivity. Similarly, Dow is advancing silicone-based TIMs and encapsulants tailored for next-generation battery modules, aiming to improve both safety and longevity.

Smart thermal management systems, integrating sensors and AI-driven controls, are also gaining traction. LG Energy Solution and Panasonic are incorporating real-time thermal monitoring and predictive algorithms into their battery management systems (BMS), enabling dynamic adjustment of cooling strategies based on usage patterns and environmental conditions. This approach not only optimizes performance but also extends battery life and enhances safety.

Automotive OEMs are actively collaborating with suppliers to bring these innovations to market. Tesla continues to refine its patented cooling ribbon technology, which weaves coolant channels directly between battery cells for efficient heat removal. Meanwhile, BMW and Mercedes-Benz are exploring modular battery pack designs that facilitate more effective integration of advanced cooling systems.

Looking ahead, the R&D pipeline for high-performance battery cooling is expected to deliver commercially viable solutions that support ultra-fast charging, higher energy densities, and improved safety. As regulatory standards tighten and consumer expectations rise, the integration of next-generation materials and smart thermal management will be pivotal in shaping the future of electrified mobility and stationary storage.

Regional Analysis: North America, Europe, Asia-Pacific, and Emerging Markets

The global landscape for high-performance battery cooling is rapidly evolving, with distinct regional trends shaping technology adoption and market growth. As electric vehicles (EVs), energy storage systems, and high-power electronics proliferate, the demand for advanced thermal management solutions is intensifying across North America, Europe, Asia-Pacific, and emerging markets.

North America remains a leader in high-performance battery cooling innovation, driven by robust EV adoption and stringent safety standards. Major automakers and battery manufacturers, such as Tesla and Ford Motor Company, are investing in liquid cooling and immersion cooling technologies to support next-generation battery packs. The U.S. Department of Energy continues to fund research into advanced thermal management, with a focus on improving energy density and cycle life. In 2025, North American suppliers are expected to accelerate the commercialization of integrated cooling plates and phase-change materials, targeting both automotive and stationary storage applications.

Europe is witnessing rapid advancements in battery cooling, propelled by aggressive decarbonization targets and a strong EV manufacturing base. Companies like BMW Group and Volkswagen AG are deploying sophisticated liquid-cooled battery modules in their latest EV models, while suppliers such as Valeo are developing compact, high-efficiency cooling systems tailored for European vehicle architectures. The European Union’s regulatory push for battery safety and recyclability is also fostering innovation in non-flammable, environmentally friendly coolants. By 2025 and beyond, Europe is expected to see increased collaboration between automakers, battery cell producers, and thermal management specialists to meet evolving performance and sustainability requirements.

Asia-Pacific dominates battery production and is a hotbed for high-performance cooling technology deployment. Leading battery manufacturers like Contemporary Amperex Technology Co. Limited (CATL) and Panasonic Corporation are scaling up advanced cooling solutions to support high-capacity, fast-charging battery systems. Chinese automakers and suppliers are rapidly adopting integrated thermal management platforms, while South Korean and Japanese firms focus on compact, modular cooling designs for both EVs and grid storage. The region’s strong government support for electrification and local supply chain development is expected to drive further innovation and cost reduction through 2025 and the following years.

Emerging markets in Latin America, the Middle East, and Africa are beginning to adopt high-performance battery cooling, primarily in commercial vehicles, buses, and stationary storage. While adoption rates are currently lower, partnerships with global OEMs and technology transfer initiatives are expected to accelerate the uptake of advanced cooling systems as electrification expands in these regions.

Future Outlook: Disruptive Trends, Investment Hotspots, and Long-Term Opportunities

The landscape for high-performance battery cooling is poised for significant transformation in 2025 and the years immediately following, driven by the accelerating adoption of electric vehicles (EVs), grid-scale energy storage, and the increasing energy density of next-generation batteries. As battery packs become more compact and powerful, the need for advanced thermal management solutions is intensifying, with a focus on safety, longevity, and fast-charging capabilities.

One of the most disruptive trends is the shift from traditional air and passive liquid cooling to active immersion and direct liquid cooling systems. Leading automotive manufacturers such as Tesla, Inc. and Bayerische Motoren Werke AG (BMW) are investing heavily in proprietary cooling architectures that integrate coolant channels directly within battery modules, enabling more uniform temperature control and supporting ultra-fast charging. LG Energy Solution and Panasonic Corporation are also advancing module-level cooling for their next-generation battery cells, targeting both automotive and stationary storage markets.

Immersion cooling, where battery cells are submerged in dielectric fluids, is gaining traction as a disruptive technology, particularly for high-performance and commercial EVs. Companies like Saft Groupe S.A. (a subsidiary of TotalEnergies) are piloting immersion-cooled battery systems for heavy-duty applications, citing improved thermal uniformity and enhanced safety margins. Meanwhile, BorgWarner Inc. and Dana Incorporated are expanding their portfolios of advanced thermal management components, including integrated chillers, heat exchangers, and smart pumps, to meet the evolving needs of OEMs.

Investment hotspots are emerging in regions with strong EV manufacturing ecosystems and government incentives for clean mobility. China, Europe, and North America are witnessing substantial capital flows into battery cooling R&D and production facilities. For example, Contemporary Amperex Technology Co. Limited (CATL) is scaling up its research into phase-change materials and advanced liquid cooling for its high-capacity battery packs, while Samsung SDI Co., Ltd. is collaborating with automakers to develop bespoke cooling solutions for premium EV platforms.

Looking ahead, long-term opportunities are expected in the integration of battery cooling with vehicle thermal management, leveraging waste heat for cabin conditioning and system efficiency. The convergence of digital twin modeling, AI-driven thermal control, and new materials (such as graphene-enhanced coolants) is likely to redefine the performance envelope of battery systems. As regulatory standards tighten and consumer expectations for fast charging and safety rise, high-performance battery cooling will remain a critical enabler of the next wave of electrification and energy storage innovation.

Sources & References

- LG Energy Solution

- International Organization for Standardization (ISO)

- Dana Incorporated

- MAHLE GmbH

- Valeo

- Siemens AG

- Hitachi Energy

- Nissan

- Hyundai Motor Company

- Shell

- Volkswagen AG

- BYD Company Limited

- Robert Bosch GmbH

- Contemporary Amperex Technology Co., Limited (CATL)

- Danfoss

- Japan Automobile Standards Internationalization Center

- Korea Automobile Testing & Research Institute

- BASF

- BorgWarner Inc.