The Critical Role of Backplane Connectors in High-Speed PCB Design: Unlocking Next-Gen Performance and Reliability. Discover the Latest Innovations and Industry Shifts Shaping Your Circuits.

- Breaking News: Recent Advances in Backplane Connector Technology

- Why Backplane Connectors Matter in High-Speed PCB Design

- Key Performance Metrics: Signal Integrity, Bandwidth, and Crosstalk

- Design Challenges and Solutions for High-Speed Backplane Integration

- Emerging Standards and Compliance Requirements

- Industry Case Studies: Success Stories and Lessons Learned

- Future Trends: AI, 5G, and the Next Wave of Backplane Innovation

- Sources & References

Breaking News: Recent Advances in Backplane Connector Technology

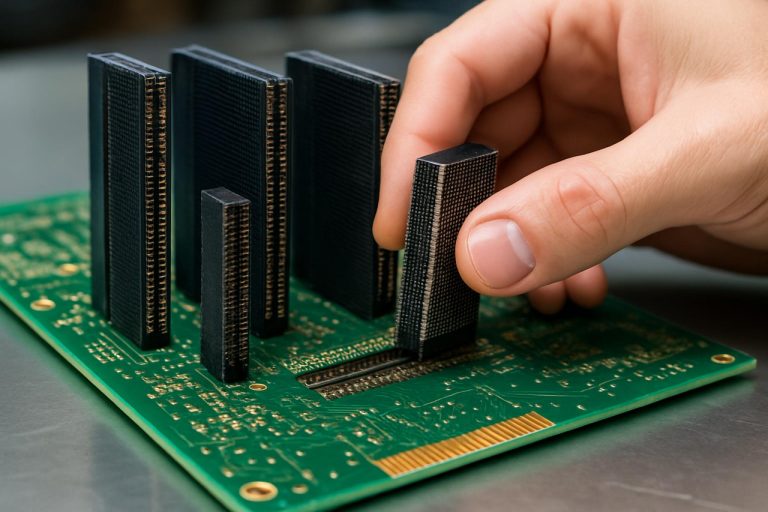

Recent advances in backplane connector technology are significantly impacting high-speed PCB design, enabling higher data rates, improved signal integrity, and greater system reliability. One of the most notable breakthroughs is the development of connectors supporting data rates beyond 56 Gbps per differential pair, addressing the growing demands of applications such as data centers, 5G infrastructure, and high-performance computing. Manufacturers are leveraging novel materials and refined contact geometries to minimize insertion loss and crosstalk, which are critical for maintaining signal quality at multi-gigabit speeds. For example, the introduction of low-profile, shielded connectors with optimized pin layouts has reduced electromagnetic interference (EMI) and improved impedance control, as highlighted by TE Connectivity.

Another significant trend is the integration of advanced manufacturing techniques, such as precision stamping and laser welding, which enhance connector consistency and mechanical robustness. Additionally, the adoption of surface-mount technology (SMT) for backplane connectors is streamlining assembly processes and enabling higher connector densities, as noted by Molex. These innovations are complemented by the use of simulation-driven design tools, allowing engineers to optimize connector performance before fabrication.

Furthermore, the industry is witnessing the emergence of modular and scalable connector systems, which facilitate easier upgrades and maintenance in complex systems. These advances collectively ensure that backplane connectors remain a critical enabler for next-generation high-speed PCB designs, supporting the relentless push for greater bandwidth and system flexibility.

Why Backplane Connectors Matter in High-Speed PCB Design

Backplane connectors play a pivotal role in high-speed PCB design, serving as the critical interface between multiple printed circuit boards within complex electronic systems. As data rates in applications such as data centers, telecommunications, and high-performance computing continue to escalate, the performance of backplane connectors directly impacts overall system integrity and reliability. High-speed signals are particularly susceptible to losses, reflections, and crosstalk at interconnect points, making the choice and design of backplane connectors a key determinant of signal quality and system bandwidth.

Modern backplane connectors are engineered to minimize insertion loss, return loss, and electromagnetic interference, all of which are essential for maintaining signal fidelity at multi-gigabit speeds. Their mechanical robustness ensures reliable mating cycles and alignment, which is crucial for systems requiring frequent module replacements or upgrades. Furthermore, advanced connector designs incorporate features such as differential pair routing, shielding, and optimized contact geometry to support high-speed serial protocols like PCIe, Ethernet, and InfiniBand Samtec.

The importance of backplane connectors extends beyond electrical performance; they also influence system scalability, thermal management, and ease of maintenance. Selecting the appropriate connector can enable higher port densities and future-proofing for next-generation data rates, while poor choices can become bottlenecks that limit system performance and upgradability Molex. In summary, backplane connectors are not merely passive components but are strategic elements that shape the capabilities and longevity of high-speed electronic systems.

Key Performance Metrics: Signal Integrity, Bandwidth, and Crosstalk

In high-speed PCB design, backplane connectors are critical components whose performance is evaluated using several key metrics: signal integrity, bandwidth, and crosstalk. Signal integrity refers to the preservation of the quality and shape of electrical signals as they traverse the connector, which is essential for minimizing data errors and ensuring reliable communication. Factors such as impedance discontinuities, insertion loss, and return loss within the connector can degrade signal integrity, especially at multi-gigabit data rates. Advanced backplane connectors are engineered with controlled impedance and optimized contact geometries to mitigate these effects, as highlighted by TE Connectivity.

Bandwidth is another crucial metric, representing the maximum frequency range over which the connector can transmit signals without significant attenuation or distortion. As data rates increase, connectors must support wider bandwidths to accommodate high-speed serial protocols like PCIe Gen5 and 400G Ethernet. The physical design, material selection, and plating of the connector contacts all influence its bandwidth capabilities, as detailed by Samtec.

Crosstalk, the unwanted coupling of signals between adjacent channels, becomes increasingly problematic as signal density and speeds rise. Excessive crosstalk can lead to data corruption and limit the achievable channel density. Modern backplane connectors employ shielding, differential pair routing, and staggered pin arrangements to minimize crosstalk, as described by Molex. Careful attention to these performance metrics is essential for ensuring robust, high-speed data transmission in advanced electronic systems.

Design Challenges and Solutions for High-Speed Backplane Integration

Integrating backplane connectors into high-speed PCB designs presents a unique set of challenges, primarily due to the stringent signal integrity requirements and the increasing data rates demanded by modern applications. One of the foremost issues is managing signal loss and reflections caused by impedance discontinuities at the connector-PCB interface. As data rates exceed 10 Gbps, even minor mismatches can result in significant degradation of signal quality, leading to increased bit error rates and reduced system reliability. Crosstalk between adjacent high-speed channels within dense connector arrays further complicates the design, necessitating careful layout and shielding strategies.

To address these challenges, designers employ several solutions. Advanced backplane connectors are engineered with controlled impedance and optimized contact geometries to minimize insertion and return losses. The use of differential signaling, along with ground shielding between pairs, helps suppress crosstalk and electromagnetic interference. Careful PCB stackup design, including the use of low-loss dielectric materials and precise trace routing, is essential to maintain signal integrity across the backplane interface. Simulation tools are widely used to model high-frequency effects and validate connector performance before fabrication, reducing the risk of costly design iterations. Additionally, compliance with industry standards such as those from IEEE and International Electrotechnical Commission (IEC) ensures interoperability and reliability in multi-vendor environments.

Ultimately, successful high-speed backplane integration hinges on a holistic approach that combines advanced connector technology, meticulous PCB design, and rigorous validation, enabling robust performance in demanding data-centric applications.

Emerging Standards and Compliance Requirements

As data rates in high-speed PCB design continue to escalate, backplane connectors must adhere to emerging standards and compliance requirements to ensure signal integrity, interoperability, and system reliability. Modern standards such as PCI Express (PCIe) Gen 5/6, Ethernet (25/50/100/400G), and the Open Compute Project (OCP) specifications are driving the evolution of backplane connector technology. These standards define stringent electrical, mechanical, and environmental parameters, including insertion loss, crosstalk, impedance control, and electromagnetic compatibility (EMC) that connectors must meet to support multi-gigabit signaling rates.

Compliance with these standards is not optional; it is essential for ensuring that backplane connectors can reliably transmit high-speed signals without excessive degradation or data errors. For example, the PCI-SIG PCIe 6.0 specification mandates extremely low insertion loss and tight impedance tolerances, while the IEEE 802.3 Ethernet standards specify return loss and crosstalk limits for backplane channels. Additionally, industry consortia such as the Open Compute Project are introducing open standards for modular, high-density backplane connectors to facilitate interoperability across vendors.

Manufacturers must validate their connector designs through rigorous compliance testing, including eye diagram analysis, bit error rate (BER) testing, and electromagnetic interference (EMI) assessments. Adhering to these emerging standards not only ensures regulatory compliance but also future-proofs designs against evolving data center and networking requirements, supporting scalability and long-term reliability in high-speed applications.

Industry Case Studies: Success Stories and Lessons Learned

Industry case studies provide valuable insights into the practical challenges and solutions associated with integrating backplane connectors in high-speed PCB designs. For instance, a leading telecommunications company faced significant signal integrity issues when upgrading its network switches to support 56 Gbps data rates. By collaborating with Molex, the company adopted advanced backplane connectors featuring optimized contact geometry and low-crosstalk design. This resulted in a 30% improvement in eye diagram performance and enabled reliable operation at higher speeds.

Another notable example comes from the data center sector, where a major server manufacturer sought to increase bandwidth without expanding the physical footprint of its backplane. By leveraging the high-density, low-insertion-loss connectors from TE Connectivity, the design team successfully doubled the channel count per backplane while maintaining signal integrity. The project highlighted the importance of early co-design between connector and PCB layout teams, as well as the use of advanced simulation tools to predict and mitigate potential issues.

However, not all implementations have been seamless. A case involving a medical imaging equipment provider revealed that insufficient attention to connector impedance matching led to unexpected EMI problems, necessitating a costly redesign. This underscores the lesson that thorough pre-layout analysis and close collaboration with connector manufacturers, such as Amphenol, are critical for success in high-speed applications.

These case studies collectively demonstrate that the right choice and integration of backplane connectors, combined with robust engineering processes, are essential for achieving high performance and reliability in demanding high-speed PCB environments.

Future Trends: AI, 5G, and the Next Wave of Backplane Innovation

The rapid evolution of technologies such as artificial intelligence (AI) and 5G is fundamentally reshaping the requirements for backplane connectors in high-speed PCB design. As AI workloads demand ever-increasing data throughput and ultra-low latency, and 5G infrastructure pushes for higher bandwidth and reliability, backplane connectors must evolve to support data rates well beyond 56 Gbps, with some next-generation designs targeting 112 Gbps and beyond. This necessitates innovations in signal integrity, crosstalk mitigation, and electromagnetic interference (EMI) shielding, as well as the adoption of advanced materials and manufacturing techniques.

AI-driven design tools are also beginning to play a significant role in optimizing connector geometry and placement, enabling predictive modeling of signal behavior and automated detection of potential bottlenecks or failure points. These tools can accelerate the development cycle and improve the performance of high-speed interconnects, as highlighted by TE Connectivity. Meanwhile, the proliferation of 5G and edge computing is driving demand for modular, scalable backplane architectures that can be easily upgraded or reconfigured to accommodate evolving standards and increased data loads, as discussed by Molex.

Looking ahead, the convergence of AI, 5G, and emerging technologies such as optical interconnects is expected to further transform backplane connector design. Hybrid electrical-optical connectors, advanced thermal management solutions, and tighter integration with system-level architectures will be critical to meeting the performance and reliability demands of next-generation high-speed PCBs.