The EV Maintenance & Aftermarket Revolution: How 2025 Will Redefine Service, Parts, and Profits for the Next Five Years. Discover the Technologies, Market Forces, and Opportunities Driving a New Era in Electric Vehicle Support.

- Executive Summary: Key Trends and Market Outlook to 2030

- Market Size, Segmentation, and 2025–2030 Growth Forecasts

- EV-Specific Maintenance Needs: Batteries, Powertrains, and Software

- Aftermarket Parts Evolution: From Legacy to High-Voltage Components

- Digitalization and Remote Diagnostics: The New Service Paradigm

- OEMs vs. Independent Service Networks: Competitive Dynamics

- Workforce Transformation: Skills, Training, and Labor Market Shifts

- Sustainability and Circular Economy in EV Aftermarket

- Regulatory Landscape and Industry Standards (e.g., SAE, IEC)

- Future Outlook: Investment, Innovation, and Strategic Opportunities

- Sources & References

Executive Summary: Key Trends and Market Outlook to 2030

The electric vehicle (EV) maintenance and aftermarket sector is undergoing rapid transformation as global EV adoption accelerates. By 2025, the cumulative global EV fleet is expected to surpass 50 million units, intensifying demand for specialized maintenance, repair, and aftermarket services. Unlike internal combustion engine (ICE) vehicles, EVs have fewer moving parts and require less frequent servicing, but they introduce new complexities around battery health, power electronics, and software updates.

Major automakers such as Tesla, Inc., Volkswagen AG, and BYD Company Ltd. are expanding their certified service networks and investing in technician training to address the unique needs of EVs. Tesla, Inc. continues to lead with over-the-air (OTA) software updates and remote diagnostics, reducing the need for physical service visits and setting new standards for digital maintenance. Meanwhile, traditional service providers and independent garages are increasingly partnering with OEMs or investing in EV-specific equipment and training to remain competitive.

Battery maintenance and replacement are emerging as the most significant aftermarket opportunities. Battery packs account for up to 40% of an EV’s value, and their longevity is a key concern for owners. Companies like Contemporary Amperex Technology Co. Limited (CATL) and LG Energy Solution are developing advanced diagnostics and second-life battery programs, while automakers are offering extended battery warranties and certified replacement services. The rise of battery recycling and refurbishment is also creating new business models and partnerships across the value chain.

The aftermarket for EV-specific components—such as electric drivetrains, inverters, and thermal management systems—is expected to grow steadily through 2030. Suppliers like Robert Bosch GmbH and ZF Friedrichshafen AG are expanding their portfolios to include high-voltage parts and diagnostic tools tailored for EVs. Additionally, the proliferation of connected vehicle technologies is enabling predictive maintenance, remote monitoring, and data-driven service offerings, further reshaping the aftermarket landscape.

Looking ahead, the EV maintenance and aftermarket sector will be shaped by continued innovation in battery technology, digitalization of service delivery, and evolving regulatory standards for safety and sustainability. As the installed base of EVs grows, the sector is poised for robust expansion, with new entrants and established players alike vying for leadership in a rapidly evolving ecosystem.

Market Size, Segmentation, and 2025–2030 Growth Forecasts

The global electric vehicle (EV) maintenance and aftermarket sector is entering a period of rapid transformation as EV adoption accelerates through 2025 and beyond. The market is being shaped by the unique characteristics of EVs—such as fewer moving parts and reduced routine maintenance needs compared to internal combustion engine (ICE) vehicles—while simultaneously creating new opportunities in battery services, software updates, and specialized components.

By 2025, the installed base of EVs is expected to surpass 50 million units worldwide, driven by strong sales in China, Europe, and North America. This expanding fleet is fueling demand for aftermarket services tailored to EVs, including battery diagnostics and replacement, high-voltage system repairs, and advanced driver-assistance system (ADAS) calibration. Major automakers such as Tesla, Volkswagen Group, and BYD are investing in dedicated service networks and digital platforms to support their growing EV customer base.

Market segmentation within the EV aftermarket is evolving. Key segments include:

- Battery Services: Battery health monitoring, refurbishment, and recycling are becoming central, with companies like CATL and Panasonic expanding their battery lifecycle management offerings.

- Software & Connectivity: Over-the-air (OTA) updates, telematics, and cybersecurity services are increasingly important, as seen in the strategies of Tesla and Nissan.

- Specialized Parts & Accessories: Demand is rising for EV-specific tires, thermal management systems, and charging hardware, with suppliers such as Bosch and Continental developing dedicated product lines.

- Service Networks: Both OEMs and independent workshops are investing in technician training and high-voltage safety equipment to address the unique requirements of EV maintenance.

Looking ahead to 2030, the EV aftermarket is projected to grow at a compound annual growth rate (CAGR) significantly outpacing the traditional automotive aftermarket, as the global EV fleet could exceed 150 million units. Battery-related services are expected to account for the largest share of aftermarket revenue, while software-driven services and remote diagnostics will become increasingly prominent. Companies with strong capabilities in battery technology, digital platforms, and global service networks—such as Tesla, BYD, and Bosch—are well positioned to lead the sector.

The next five years will see the EV maintenance and aftermarket landscape become more specialized, data-driven, and competitive, with new business models emerging around battery leasing, predictive maintenance, and circular economy solutions.

EV-Specific Maintenance Needs: Batteries, Powertrains, and Software

The shift to electric vehicles (EVs) is fundamentally transforming automotive maintenance, with a pronounced focus on batteries, powertrains, and software. As of 2025, the EV maintenance landscape is shaped by the unique characteristics of these components, diverging significantly from traditional internal combustion engine (ICE) vehicles.

Batteries are the most critical and expensive component in EVs, dictating both performance and longevity. Unlike ICE vehicles, EVs require regular battery health diagnostics, thermal management checks, and, over time, potential module replacements. Leading manufacturers such as Tesla, Inc. and Nissan Motor Corporation have established dedicated battery service protocols, including advanced diagnostic tools and battery recycling initiatives. Battery warranties typically span 8 years or 100,000 miles, but as EVs age, aftermarket demand for battery refurbishment and second-life applications is expected to rise. Companies like LG Energy Solution and Contemporary Amperex Technology Co., Limited (CATL) are also investing in battery lifecycle management and recycling infrastructure to support this growing need.

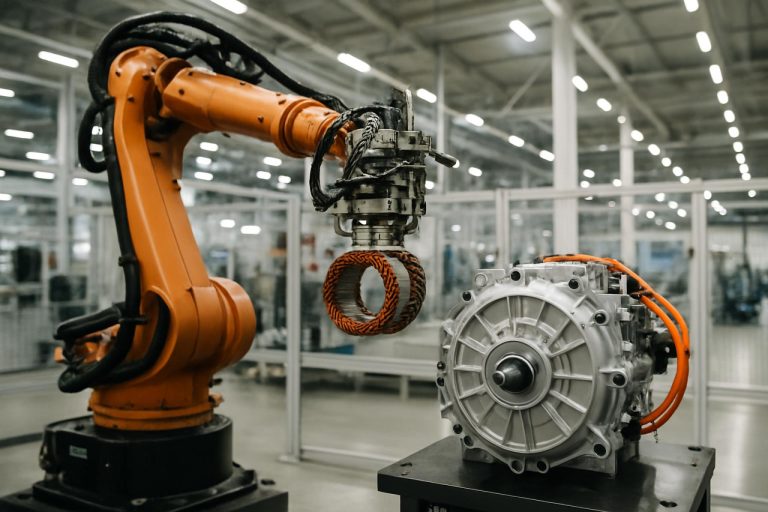

Powertrains in EVs are mechanically simpler than their ICE counterparts, with fewer moving parts and reduced need for routine maintenance such as oil changes or transmission repairs. However, specialized attention is required for components like electric motors, inverters, and reduction gears. Automakers including Bayerische Motoren Werke AG (BMW) and Ford Motor Company are training technicians in high-voltage safety and diagnostics, reflecting the evolving skill set required in the aftermarket sector. The reduced mechanical wear in EV powertrains is expected to lower overall maintenance costs, but the need for specialized service centers and certified parts is increasing.

Software is emerging as a central pillar of EV maintenance. Over-the-air (OTA) updates, pioneered by Tesla, Inc., are now being adopted by other major OEMs such as Volkswagen AG and Hyundai Motor Company. These updates can address performance, safety, and even battery management issues remotely, reducing the frequency of physical service visits. However, software-related diagnostics and cybersecurity are becoming new areas of aftermarket specialization, with manufacturers and third-party providers developing tools to ensure system integrity and compliance with evolving regulations.

Looking ahead, the EV aftermarket is poised for rapid evolution. As the global EV fleet expands, demand for battery servicing, powertrain expertise, and software support will intensify. Automakers and suppliers are investing in technician training, digital diagnostic platforms, and battery recycling to meet these needs, signaling a shift toward a more technologically advanced and sustainable maintenance ecosystem.

Aftermarket Parts Evolution: From Legacy to High-Voltage Components

The rapid adoption of electric vehicles (EVs) is fundamentally transforming the automotive aftermarket, shifting the focus from traditional internal combustion engine (ICE) components to high-voltage and electronic systems. As of 2025, the global EV parc is expanding swiftly, with major automakers such as Tesla, Volkswagen AG, and BYD Company leading the charge in both vehicle production and the development of proprietary parts ecosystems. This evolution is driving significant changes in the types of parts and services demanded by consumers and fleets.

Historically, the aftermarket has been dominated by components such as oil filters, spark plugs, exhaust systems, and timing belts—parts that are either absent or radically different in EVs. Instead, the new wave of aftermarket demand centers on high-voltage batteries, power electronics, electric drive units, thermal management systems, and advanced software updates. For example, Tesla has established a vertically integrated approach, controlling much of its parts supply and service network, while also beginning to open up select parts and repair information to independent shops in response to regulatory pressures and customer demand.

Battery replacement and refurbishment are emerging as key aftermarket segments. Companies like BYD Company and Nissan Motor Corporation are investing in battery recycling and second-life programs, aiming to extend the value chain beyond the vehicle’s first life. High-voltage safety components, such as insulation, connectors, and fuses, are also seeing increased demand, with suppliers like Robert Bosch GmbH and Continental AG expanding their portfolios to include specialized EV parts.

The aftermarket is also being shaped by the growing importance of software and diagnostics. Over-the-air (OTA) updates, remote diagnostics, and cybersecurity solutions are becoming integral to vehicle maintenance, with companies such as Tesla and Volkswagen AG regularly deploying software enhancements that can affect vehicle performance and safety. This trend is prompting traditional parts suppliers to invest in digital platforms and training for independent workshops.

Looking ahead, the next few years will likely see further consolidation among parts suppliers, increased collaboration between OEMs and independent aftermarket players, and the emergence of new business models centered on battery health monitoring, predictive maintenance, and component remanufacturing. As EVs become more prevalent, the aftermarket will continue its shift from legacy mechanical parts to high-voltage, electronic, and software-driven components, fundamentally redefining the landscape of vehicle maintenance and repair.

Digitalization and Remote Diagnostics: The New Service Paradigm

The rapid digitalization of the automotive sector is fundamentally transforming the maintenance and aftermarket landscape for electric vehicles (EVs) in 2025 and beyond. As EVs become increasingly software-driven, remote diagnostics and over-the-air (OTA) updates are emerging as central pillars of the new service paradigm. This shift is being led by both established automakers and innovative technology providers, aiming to reduce downtime, enhance customer experience, and optimize operational efficiency.

One of the most prominent examples is Tesla, Inc., which has pioneered the use of OTA software updates to address vehicle performance, safety, and even recall issues without requiring physical service center visits. In 2024 and 2025, Tesla continues to expand its remote diagnostic capabilities, allowing technicians to pre-diagnose issues and, in many cases, resolve them remotely or prepare parts and instructions in advance for service appointments. This approach significantly reduces service times and costs for both customers and the company.

Other major automakers are following suit. Volkswagen AG has rolled out its “We Connect” platform, enabling remote monitoring and diagnostics for its ID. series EVs. Similarly, Ford Motor Company is leveraging its “Power-Up” OTA update system to deliver new features and maintenance fixes to its Mustang Mach-E and F-150 Lightning models. These digital platforms not only facilitate remote troubleshooting but also collect valuable data to predict component wear and schedule preventive maintenance, reducing unexpected breakdowns.

Tier 1 suppliers and technology firms are also playing a crucial role. Robert Bosch GmbH is developing advanced telematics and cloud-based diagnostic solutions that integrate with OEM systems, enabling real-time health monitoring of EV batteries, power electronics, and drivetrains. Continental AG is investing in predictive maintenance algorithms and secure data transmission to support remote diagnostics across multiple brands and platforms.

Industry bodies such as the European Automobile Manufacturers’ Association (ACEA) and SAE International are working to standardize data protocols and cybersecurity frameworks, ensuring interoperability and data privacy as digitalization accelerates.

Looking ahead, the integration of artificial intelligence and machine learning is expected to further enhance remote diagnostics, enabling more accurate fault prediction and automated service scheduling. As EV adoption grows, digital service models are poised to become the industry norm, reshaping the aftermarket ecosystem and creating new opportunities for OEMs, suppliers, and independent service providers alike.

OEMs vs. Independent Service Networks: Competitive Dynamics

The competitive landscape for electric vehicle (EV) maintenance and aftermarket services is rapidly evolving as the global EV fleet expands in 2025. Original Equipment Manufacturers (OEMs) are leveraging their technological edge and proprietary systems to retain a dominant position in servicing their vehicles, while independent service networks (ISNs) are striving to adapt and capture a share of this growing market.

OEMs such as Tesla, Inc., Volkswagen AG, and BYD Company Ltd. have established extensive branded service networks, often integrating over-the-air (OTA) diagnostics and software updates that limit the need for physical service visits. Tesla, for example, continues to expand its global service center footprint and mobile service fleet, emphasizing direct customer relationships and proprietary repair protocols. Similarly, Volkswagen is investing in specialized EV training for its dealer network and rolling out dedicated EV service centers to support its ID. family of vehicles.

A key competitive advantage for OEMs lies in their control over diagnostic tools, software, and genuine parts. Many EVs require specialized equipment and software access for even routine maintenance, which OEMs often restrict to their authorized networks. This approach not only ensures quality control but also creates barriers for independent workshops. For instance, Renault Group and Nissan Motor Corporation have both developed proprietary battery health assessment tools, which are essential for warranty and resale evaluations.

Independent service networks, including established chains and new entrants, are responding by investing in technician training, EV-specific tooling, and partnerships with parts suppliers. Companies like Robert Bosch GmbH are developing universal diagnostic platforms and aftermarket battery solutions to support multi-brand EV servicing. Bosch, in particular, is collaborating with workshops to provide access to EV repair data and components, aiming to level the playing field with OEMs.

Regulatory developments in regions such as the European Union are also shaping the competitive dynamics. The EU’s push for “right to repair” legislation is compelling OEMs to share more technical information with independent operators, potentially increasing competition in the aftermarket. However, the complexity and rapid evolution of EV technology mean that ISNs must continually invest in upskilling and equipment to remain relevant.

Looking ahead, the balance of power between OEMs and ISNs in EV maintenance will likely hinge on access to data, software, and parts. While OEMs are expected to maintain a stronghold in the near term, especially for high-voltage battery and software-related services, the aftermarket is poised for gradual liberalization as technology matures and regulatory frameworks evolve.

Workforce Transformation: Skills, Training, and Labor Market Shifts

The rapid adoption of electric vehicles (EVs) is fundamentally transforming the automotive workforce, particularly in the maintenance and aftermarket sectors. As of 2025, the shift from internal combustion engine (ICE) vehicles to EVs is accelerating, driven by regulatory mandates, consumer demand, and automaker commitments to electrification. This transition is reshaping the skills landscape, training requirements, and labor market dynamics for technicians and service providers.

EVs have fewer moving parts and require less routine maintenance than traditional vehicles, but they introduce new complexities related to high-voltage systems, battery management, and advanced electronics. As a result, there is a growing demand for technicians with specialized knowledge in areas such as battery diagnostics, electric drivetrains, and software-based vehicle systems. Major automakers, including Ford Motor Company and General Motors, have launched extensive training programs to upskill their dealer and service networks. For example, Ford’s “Electric University” initiative is designed to certify thousands of technicians in EV-specific maintenance and safety protocols, while GM’s “EV First Responder Training” targets both dealership staff and independent repair shops.

The aftermarket sector is also evolving. Companies like Robert Bosch GmbH are investing in new diagnostic tools and service equipment tailored for EVs, and are collaborating with vocational schools and technical institutes to update curricula. The Nissan Motor Corporation has established dedicated EV training centers in key markets, focusing on battery servicing and recycling, which are expected to become major growth areas as early EVs reach end-of-life.

Industry bodies such as the National Automobile Dealers Association and the National Institute for Automotive Service Excellence are updating certification standards and offering new credentials for EV maintenance. These efforts are critical, as a 2024 survey by the ASE found that less than 10% of current automotive technicians feel fully prepared to service EVs, highlighting a significant skills gap.

Looking ahead, the labor market is expected to see a bifurcation: while demand for traditional ICE maintenance roles will decline, opportunities for EV specialists will grow. The U.S. Bureau of Labor Statistics projects that by 2030, EV-related service jobs could account for up to 25% of all automotive technician positions. To meet this demand, partnerships between automakers, suppliers, and educational institutions are likely to intensify, with a focus on continuous learning and certification renewal as EV technologies evolve.

Sustainability and Circular Economy in EV Aftermarket

The transition to electric vehicles (EVs) is reshaping the automotive aftermarket, with sustainability and circular economy principles becoming central to maintenance, repair, and parts management. As of 2025, the EV aftermarket is witnessing a surge in initiatives aimed at reducing waste, extending component lifecycles, and minimizing environmental impact.

A key focus is on battery lifecycle management. Major EV manufacturers and battery suppliers are investing in battery recycling and repurposing programs to address the environmental challenges posed by end-of-life lithium-ion batteries. Tesla, Inc. operates in-house battery recycling facilities, aiming to recover valuable materials such as nickel, cobalt, and lithium for reuse in new battery production. Similarly, Nissan Motor Corporation has established partnerships to repurpose used EV batteries for stationary energy storage, supporting grid stability and renewable integration.

Automotive suppliers are also advancing remanufacturing and refurbishment of EV components. Robert Bosch GmbH, a leading global supplier, has expanded its remanufacturing services to include electric drive modules and power electronics, reducing the need for new raw materials and lowering the carbon footprint of replacement parts. Continental AG is similarly developing circular solutions for EV-specific parts, such as sensors and control units, to extend their usable life and facilitate responsible end-of-life processing.

The tire sector is adapting to the unique demands of EVs, which often require specialized, low-rolling-resistance tires. Michelin and Bridgestone Corporation are investing in sustainable tire materials and recycling programs, aiming to close the loop on tire production and disposal. These efforts are complemented by digital platforms that monitor tire wear and optimize replacement cycles, further reducing waste.

Looking ahead, regulatory frameworks in key markets are expected to accelerate the adoption of circular economy practices in the EV aftermarket. The European Union’s Battery Regulation, effective from 2025, mandates higher recycling rates and traceability for battery materials, influencing global supply chains and aftermarket operations. Automakers and suppliers are responding by enhancing transparency and developing take-back schemes to ensure compliance and support sustainability goals.

In summary, the EV aftermarket in 2025 is increasingly defined by sustainability and circularity, with industry leaders investing in recycling, remanufacturing, and digitalization. These trends are set to intensify over the next few years, as regulatory pressures mount and the volume of end-of-life EV components grows, driving innovation and collaboration across the sector.

Regulatory Landscape and Industry Standards (e.g., SAE, IEC)

The regulatory landscape and industry standards for electric vehicle (EV) maintenance and the aftermarket are rapidly evolving as the global EV fleet expands. In 2025 and the coming years, harmonization of standards and the introduction of new regulations are expected to play a pivotal role in shaping service protocols, safety requirements, and parts interoperability.

Key international standards bodies such as the SAE International and the International Electrotechnical Commission (IEC) continue to update and expand guidelines for EV servicing. SAE’s J-standard series, including J1772 (charging connectors) and J2954 (wireless charging), are being complemented by new standards addressing high-voltage system safety, battery diagnostics, and repairability. The IEC, meanwhile, is advancing standards like IEC 61851 (charging systems) and IEC 62984 (battery safety), which are increasingly referenced in national regulations.

In the European Union, the regulatory framework is being strengthened through the implementation of the European Automobile Manufacturers’ Association (ACEA) guidelines and the EU’s End-of-Life Vehicles Directive, which now includes specific provisions for EV batteries and components. These regulations mandate safe handling, traceability, and recycling of high-voltage batteries, directly impacting aftermarket service providers and recyclers.

In the United States, the National Highway Traffic Safety Administration (NHTSA) and the Environmental Protection Agency (EPA) are collaborating on updated safety and environmental standards for EV maintenance, including requirements for battery storage, transport, and disposal. The UL (Underwriters Laboratories) is also active in certifying EV service equipment and components, ensuring compliance with evolving safety benchmarks.

Automakers such as Tesla, Inc., Volkswagen AG, and Toyota Motor Corporation are increasingly aligning their service protocols with these standards, while also developing proprietary diagnostic tools and training programs for independent workshops. This is fostering a more open aftermarket, though challenges remain regarding access to repair data and specialized parts.

Looking ahead, the convergence of global standards is expected to facilitate cross-border servicing and parts supply, while regulatory focus on battery lifecycle management will drive innovation in diagnostics, refurbishment, and recycling. The next few years will likely see further integration of digital compliance tools and remote diagnostics, as regulators and industry bodies respond to the growing complexity of EV maintenance and the need for safe, sustainable aftermarket practices.

Future Outlook: Investment, Innovation, and Strategic Opportunities

The future of electric vehicle (EV) maintenance and the aftermarket sector is poised for significant transformation as the global EV fleet expands rapidly through 2025 and beyond. With EV adoption accelerating, industry stakeholders are investing in new technologies, workforce training, and service models to address the unique requirements of electric drivetrains, battery systems, and digital vehicle architectures.

Major automakers are leading the charge in shaping the EV aftermarket landscape. Tesla, Inc. continues to expand its proprietary service network, integrating over-the-air diagnostics and software updates to minimize physical service visits. Meanwhile, Ford Motor Company and General Motors are investing in technician training and digital platforms to support their growing EV portfolios, with a focus on battery health monitoring and predictive maintenance.

Battery lifecycle management is emerging as a central theme. Companies such as Contemporary Amperex Technology Co., Limited (CATL) and LG Energy Solution are collaborating with automakers to develop battery diagnostics, refurbishment, and recycling programs. These initiatives are critical as battery packs represent the most valuable and complex component in EVs, and their longevity directly impacts total cost of ownership and residual values.

The aftermarket is also witnessing the entry of specialized service providers and parts suppliers. Robert Bosch GmbH is expanding its portfolio of EV-specific diagnostic tools, charging solutions, and replacement parts, while ZF Friedrichshafen AG is developing modular components and training programs for independent workshops. These efforts aim to democratize EV maintenance expertise beyond OEM networks, fostering a more competitive and accessible aftermarket ecosystem.

Looking ahead, digitalization and data-driven services are expected to play a pivotal role. Predictive analytics, remote diagnostics, and connected vehicle platforms will enable proactive maintenance, reducing downtime and enhancing customer experience. Strategic investments in technician upskilling, battery management infrastructure, and digital service platforms are likely to accelerate through the late 2020s, as the installed base of EVs grows and vehicles age into the aftermarket.

In summary, the EV maintenance and aftermarket sector is entering a phase of rapid innovation and investment. Collaboration between automakers, battery manufacturers, technology suppliers, and independent service providers will be essential to address evolving technical challenges and unlock new value streams in the years ahead.

Sources & References

- Volkswagen AG

- BYD Company Ltd.

- Contemporary Amperex Technology Co. Limited (CATL)

- LG Energy Solution

- Robert Bosch GmbH

- ZF Friedrichshafen AG

- Nissan

- Hyundai Motor Company

- European Automobile Manufacturers’ Association (ACEA)

- Renault Group

- General Motors

- National Automobile Dealers Association

- Michelin

- Bridgestone Corporation

- UL (Underwriters Laboratories)

- Toyota Motor Corporation