Unlocking the Secrets of Lunar Regolith Simulants: How Earth-Made Moon Dust Is Powering the Next Generation of Space Exploration

- What Are Lunar Regolith Simulants?

- Why Simulate Moon Dust? The Critical Role in Space Research

- How Lunar Regolith Simulants Are Made: Materials and Methods

- Comparing Simulants to Real Lunar Soil: Accuracy and Limitations

- Applications: Testing Technologies for Lunar Bases and Rovers

- Challenges and Innovations in Simulant Development

- Future Directions: Next-Gen Simulants and Their Impact on Artemis and Beyond

- Sources & References

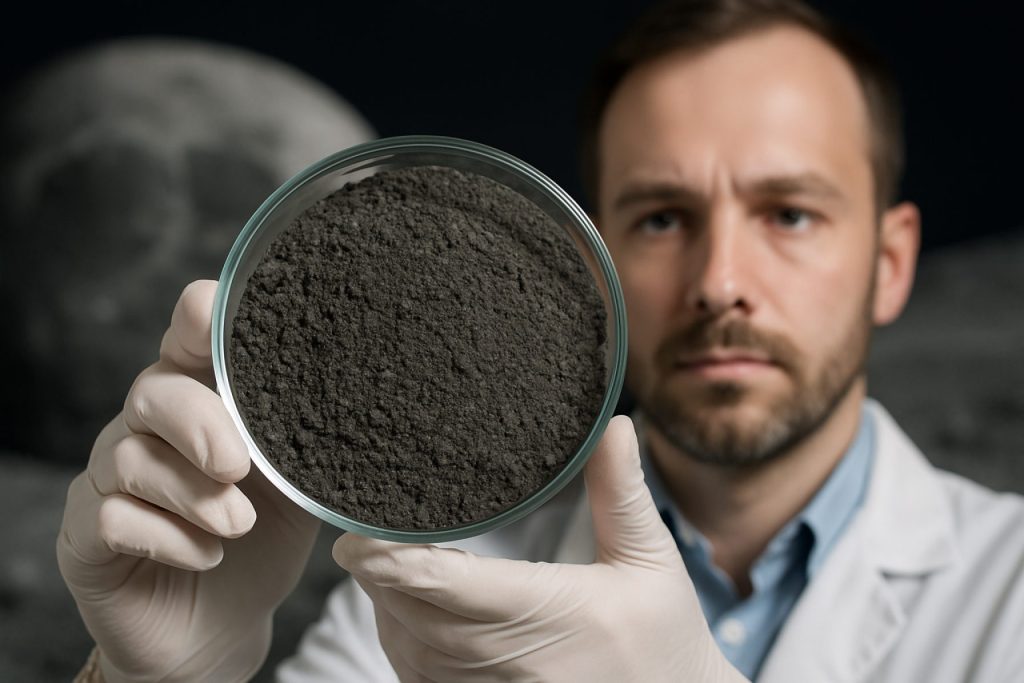

What Are Lunar Regolith Simulants?

Lunar regolith simulants are engineered materials designed to closely replicate the physical, chemical, and mineralogical properties of the Moon’s surface soil, known as regolith. These simulants are essential for terrestrial research and development activities related to lunar exploration, including testing of equipment, development of construction techniques, and assessment of life support systems. Since actual lunar regolith is scarce and difficult to obtain, simulants provide a practical and cost-effective alternative for scientific and engineering purposes.

The development of lunar regolith simulants involves detailed analysis of samples returned from the Apollo missions, as well as data from remote sensing and robotic missions. Simulants are typically produced from terrestrial materials that are processed to match the grain size distribution, mineral composition, and mechanical properties of lunar soil. For example, the widely used JSC-1A simulant is derived from volcanic ash in the United States and is engineered to mimic the basaltic highland soils found on the Moon’s surface NASA Johnson Space Center.

Different simulants are tailored to represent specific lunar regions, such as the mare or highlands, and may include variations in glass content, particle angularity, and magnetic properties. The use of these simulants enables researchers to evaluate the performance of technologies under lunar-like conditions, supporting mission planning and risk reduction for future lunar operations Lunar and Planetary Institute. As lunar exploration advances, the demand for more accurate and specialized simulants continues to grow, driving ongoing refinement and innovation in their production.

Why Simulate Moon Dust? The Critical Role in Space Research

Simulating Moon dust, or lunar regolith, is essential for advancing space research and preparing for future lunar missions. The unique properties of lunar regolith—its sharp, abrasive particles, chemical reactivity, and lack of moisture—pose significant challenges for both human explorers and robotic systems. However, direct access to actual Moon dust is extremely limited, with only a small quantity brought back by Apollo and Luna missions. As a result, scientists have developed lunar regolith simulants: terrestrial materials engineered to closely mimic the physical, chemical, and mechanical characteristics of genuine lunar soil.

These simulants play a critical role in a wide range of research and development activities. They enable the testing of life support systems, dust mitigation technologies, and habitat construction methods under realistic conditions. For example, simulants are used to evaluate the performance and durability of spacesuits, seals, and mechanical joints, which can be compromised by the abrasive nature of lunar dust. They are also vital for developing and validating in-situ resource utilization (ISRU) techniques, such as extracting oxygen or building materials from regolith, which are key to sustainable lunar exploration and habitation NASA.

Furthermore, lunar regolith simulants support the calibration and testing of scientific instruments destined for the Moon, ensuring accurate data collection once deployed. By providing a safe, accessible, and cost-effective alternative to real Moon dust, these simulants are indispensable for reducing mission risks and accelerating technological innovation in lunar exploration European Space Agency (ESA).

How Lunar Regolith Simulants Are Made: Materials and Methods

Lunar regolith simulants are engineered materials designed to replicate the physical, chemical, and mineralogical properties of the Moon’s surface soil, or regolith. The production of these simulants involves a careful selection of terrestrial source materials and precise processing methods to mimic the unique characteristics of lunar soil. The process typically begins with the identification of terrestrial rocks and minerals that closely resemble those found in lunar samples, such as basalts, anorthosites, and volcanic glasses. These source materials are then crushed, milled, and sieved to achieve the desired particle size distribution, which is critical for simulating the texture and mechanical behavior of lunar regolith.

Chemical composition is another key consideration. Simulant developers often blend different minerals to match the major and minor oxide contents observed in actual lunar samples, as documented by the NASA Johnson Space Center. In some cases, additives such as glassy components or agglutinates are incorporated to replicate the effects of micrometeoroid impacts and space weathering, which are prevalent on the Moon but absent on Earth. Advanced simulants may also undergo thermal processing to create glassy phases or to alter mineral structures, further enhancing their fidelity.

Quality control and characterization are essential throughout the process. Simulants are analyzed using techniques such as X-ray diffraction, scanning electron microscopy, and particle size analysis to ensure they meet the required specifications. The resulting materials are then distributed to researchers and engineers for use in testing technologies for lunar exploration, including excavation, construction, and life support systems NASA.

Comparing Simulants to Real Lunar Soil: Accuracy and Limitations

Lunar regolith simulants are engineered materials designed to mimic the physical and chemical properties of actual lunar soil, enabling terrestrial research and technology development for lunar exploration. However, the accuracy of these simulants in replicating real lunar regolith is subject to several limitations. While simulants such as JSC-1A, NU-LHT, and others are formulated based on data from Apollo samples, they often fall short in reproducing certain critical characteristics. For instance, the unique angularity, glass content, and nanophase iron particles found in lunar regolith—formed by billions of years of micrometeoroid impacts and solar wind exposure—are challenging to replicate on Earth NASA.

Chemical composition is another area where simulants diverge from authentic lunar soil. While major oxides and mineral phases can be matched closely, trace elements and volatile content often differ, potentially affecting experiments related to resource extraction or dust mitigation Lunar and Planetary Institute. Additionally, the absence of space weathering processes in simulants means they lack the mature regolith’s surface chemistry and electrostatic properties, which are crucial for understanding dust behavior and equipment interactions on the Moon.

Despite these limitations, lunar regolith simulants remain indispensable for mission planning, hardware testing, and astronaut training. Ongoing efforts aim to improve their fidelity by incorporating advanced manufacturing techniques and updated lunar data from recent missions European Space Agency. Nevertheless, researchers must carefully consider these differences when interpreting experimental results and extrapolating findings to actual lunar conditions.

Applications: Testing Technologies for Lunar Bases and Rovers

Lunar regolith simulants play a pivotal role in the development and validation of technologies intended for lunar bases and rovers. Since direct access to actual lunar soil is extremely limited, these simulants—engineered to closely mimic the physical, chemical, and mechanical properties of genuine lunar regolith—enable researchers and engineers to conduct realistic testing on Earth. Applications include evaluating the performance and durability of construction materials, dust mitigation systems, excavation tools, and mobility platforms under simulated lunar surface conditions. For instance, simulants are used to assess how lunar dust may affect the moving parts of rovers or the efficiency of air filtration systems in habitats, helping to anticipate and mitigate operational challenges before deployment on the Moon.

Moreover, lunar regolith simulants are essential for testing in-situ resource utilization (ISRU) technologies, such as extracting oxygen or building materials from lunar soil, which are critical for sustainable lunar habitation. Simulants allow for iterative experimentation and optimization of these processes without the prohibitive costs and risks associated with using actual lunar samples. Agencies like NASA and organizations such as the Lunar and Planetary Institute have developed standardized simulants to ensure consistency and reliability in testing. As lunar exploration efforts intensify, the continued refinement and application of regolith simulants will remain fundamental to the safe and effective design of lunar infrastructure and robotic systems.

Challenges and Innovations in Simulant Development

Developing accurate lunar regolith simulants presents significant challenges due to the unique properties of actual lunar soil. The Moon’s regolith is formed through billions of years of micrometeorite impacts, resulting in a highly angular, fine, and glass-rich material with distinct mineralogy and particle size distribution. Replicating these features on Earth is difficult, as terrestrial materials often lack the same composition and mechanical properties. For instance, lunar regolith contains agglutinates—glassy, welded particles formed by micrometeoroid impacts—which are rare in Earth-sourced materials. Additionally, the absence of weathering processes on the Moon means lunar dust is sharper and more abrasive than its terrestrial counterparts, posing further challenges for simulant fidelity NASA.

To address these challenges, researchers have developed innovative approaches. Advanced processing techniques, such as high-temperature melting and rapid quenching, are used to create glassy components and agglutinates in simulants. Mineralogical matching is achieved by blending specific terrestrial rocks, such as basalts and anorthosites, to approximate the chemical and physical properties of lunar regolith. Recent innovations also include the use of additive manufacturing and nanotechnology to better mimic the particle morphology and surface chemistry of lunar dust. Standardization efforts, such as those led by ASTM International, aim to ensure consistency and reliability in simulant production, facilitating their use in technology testing, habitat construction, and life support system development for future lunar missions.

Future Directions: Next-Gen Simulants and Their Impact on Artemis and Beyond

As lunar exploration accelerates under programs like NASA’s Artemis, the demand for advanced lunar regolith simulants is intensifying. Next-generation simulants are being engineered to more precisely replicate the complex physical, chemical, and mineralogical properties of actual lunar soil, including its particle size distribution, glass content, and volatile components. These improvements are critical for testing technologies such as in-situ resource utilization (ISRU), dust mitigation systems, and habitat construction, all of which are central to sustainable lunar operations.

Emerging simulants are incorporating features previously overlooked, such as nanophase iron and agglutinate content, which are key to understanding lunar dust’s abrasive and reactive behavior. Additionally, simulants tailored to specific lunar regions—like the permanently shadowed regions at the lunar south pole, which may contain water ice—are under development to support Artemis’s targeted landing sites. These region-specific simulants enable more accurate testing of excavation, extraction, and processing technologies for water and other volatiles, which are vital for life support and fuel production.

The impact of these next-gen simulants extends beyond Artemis. They are essential for international lunar missions, commercial ventures, and academic research, fostering global collaboration and innovation. As simulant fidelity increases, so does the reliability of ground-based testing, reducing mission risk and cost. The ongoing evolution of lunar regolith simulants is thus a cornerstone for the future of lunar science and exploration, supporting not only Artemis but also the broader vision of a sustainable human presence on the Moon and beyond NASA Lunar and Planetary Institute.