Lunar Regolith Utilization Technologies in 2025: Pioneering the Next Frontier of Space Resource Extraction. Explore How Advanced Solutions Are Transforming Moon Dust into the Foundation of Lunar Industry and Infrastructure.

- Executive Summary: The 2025 Lunar Regolith Opportunity

- Market Size & Forecast: 2025–2030 Growth Projections (CAGR 28%)

- Key Drivers: Why Lunar Regolith Utilization Is Accelerating

- Technology Landscape: Extraction, Processing, and Manufacturing Innovations

- Leading Players & Emerging Startups

- Applications: Construction, Life Support, Propellant, and Beyond

- Regulatory and Policy Environment

- Investment Trends and Funding Landscape

- Challenges and Barriers to Adoption

- Future Outlook: Roadmap to 2030 and Beyond

- Sources & References

Executive Summary: The 2025 Lunar Regolith Opportunity

The year 2025 marks a pivotal moment for lunar regolith utilization technologies, as international space agencies and private sector leaders accelerate efforts to harness the Moon’s surface materials for sustainable exploration and commercial development. Lunar regolith—the layer of loose, fragmented material covering the Moon’s bedrock—offers a unique opportunity to support in-situ resource utilization (ISRU), reducing the need to transport supplies from Earth and enabling longer, more cost-effective missions.

Recent advancements in regolith processing, additive manufacturing, and resource extraction are converging to make lunar regolith a cornerstone of future lunar infrastructure. Technologies under development aim to convert regolith into construction materials, oxygen, water, and even rocket propellant. For example, NASA’s Artemis program is investing in regolith-based 3D printing for habitat construction, while European Space Agency (ESA) initiatives focus on extracting oxygen and metals from lunar soil. These efforts are complemented by private sector innovation, with companies like Blue Origin and ispace, inc. developing regolith handling and processing systems for commercial lunar operations.

The 2025 landscape is shaped by a growing consensus that lunar regolith utilization is essential for establishing a sustainable human presence on the Moon. Key drivers include the need for local construction materials to build landing pads, habitats, and radiation shielding, as well as the extraction of life-supporting elements. The maturation of ISRU technologies is also expected to catalyze new business models, from lunar mining to the production of consumables for deep space missions.

Strategic partnerships between government agencies and industry are accelerating technology demonstration missions, with several lunar landers and rovers scheduled to test regolith processing techniques in situ. The Japan Aerospace Exploration Agency (JAXA) and China National Space Administration (CNSA) are also advancing parallel initiatives, underscoring the global nature of this opportunity.

In summary, 2025 is set to be a transformative year for lunar regolith utilization technologies, with significant implications for lunar settlement, resource independence, and the broader cislunar economy. Stakeholders who invest in and adapt to these emerging capabilities will be well-positioned to lead in the next era of space exploration.

Market Size & Forecast: 2025–2030 Growth Projections (CAGR 28%)

The market for lunar regolith utilization technologies is poised for significant expansion between 2025 and 2030, driven by increasing investments in lunar exploration and the growing emphasis on in-situ resource utilization (ISRU) to support sustainable lunar missions. Lunar regolith, the layer of loose, heterogeneous material covering the Moon’s surface, is being targeted for extraction and processing to produce construction materials, oxygen, water, and metals—critical resources for long-term lunar habitation and infrastructure development.

According to projections, the global market for lunar regolith utilization technologies is expected to achieve a compound annual growth rate (CAGR) of approximately 28% during the 2025–2030 period. This robust growth is underpinned by several key factors:

- Governmental Initiatives: Major space agencies, including National Aeronautics and Space Administration (NASA) and European Space Agency (ESA), have prioritized ISRU in their Artemis and Moon Village programs, respectively, allocating substantial funding for technology development and demonstration missions.

- Commercial Partnerships: The emergence of public-private partnerships, such as those fostered by NASA’s Commercial Lunar Payload Services (CLPS) initiative, is accelerating the deployment of regolith processing payloads and pilot plants on the lunar surface.

- Technological Advancements: Innovations in robotic mining, additive manufacturing, and chemical processing are reducing the technical barriers to extracting and utilizing lunar regolith, making commercial-scale operations increasingly viable.

- Strategic Industry Investments: Leading aerospace companies, such as Lockheed Martin Corporation and Northrop Grumman Corporation, are investing in regolith-based construction and resource extraction technologies, anticipating future demand from lunar bases and infrastructure projects.

By 2030, the market is projected to reach several hundred million dollars in annual value, with the potential for exponential growth as lunar infrastructure projects transition from demonstration to operational phases. The rapid expansion of this market segment is expected to catalyze new business models, supply chains, and international collaborations, positioning lunar regolith utilization as a cornerstone of the emerging cislunar economy.

Key Drivers: Why Lunar Regolith Utilization Is Accelerating

The acceleration of lunar regolith utilization technologies is driven by a convergence of scientific, economic, and strategic imperatives. As international interest in sustained lunar presence intensifies, the ability to harness local resources—particularly regolith, the Moon’s ubiquitous surface material—has become central to mission planning and long-term viability.

A primary driver is the cost and complexity of transporting materials from Earth. Launching payloads to the Moon remains prohibitively expensive, with every kilogram saved translating into significant financial and logistical benefits. By developing technologies to extract oxygen, water, and construction materials from lunar regolith, agencies like National Aeronautics and Space Administration (NASA) and European Space Agency (ESA) aim to reduce dependence on Earth-based supply chains, enabling more ambitious and sustainable exploration architectures.

Another key factor is the strategic value of in-situ resource utilization (ISRU) for future crewed missions and lunar infrastructure. Regolith-derived oxygen can support life support systems and fuel production, while metals and silicates can be used for building habitats, landing pads, and radiation shielding. This approach aligns with the goals of programs such as NASA’s Artemis, which envisions a permanent human presence on the Moon as a stepping stone to Mars and beyond.

Technological advancements are also propelling the field forward. Innovations in additive manufacturing, chemical processing, and robotics have made it increasingly feasible to process regolith on-site. For example, ESA has demonstrated 3D printing techniques using simulated lunar soil, while NASA is funding private sector efforts to develop regolith-based construction and extraction systems.

Finally, international collaboration and commercial interest are accelerating progress. The emergence of lunar resource policies and partnerships, such as those fostered by the Artemis Accords, is creating a framework for shared investment and technology development. As more stakeholders recognize the Moon’s potential as a resource hub, the pace of innovation and deployment in regolith utilization technologies is expected to intensify through 2025 and beyond.

Technology Landscape: Extraction, Processing, and Manufacturing Innovations

The technological landscape for lunar regolith utilization is rapidly evolving, driven by the renewed global interest in sustainable lunar exploration and in-situ resource utilization (ISRU). In 2025, significant advancements are being made in the extraction, processing, and manufacturing of materials derived from lunar regolith, the layer of loose, heterogeneous material covering the Moon’s surface.

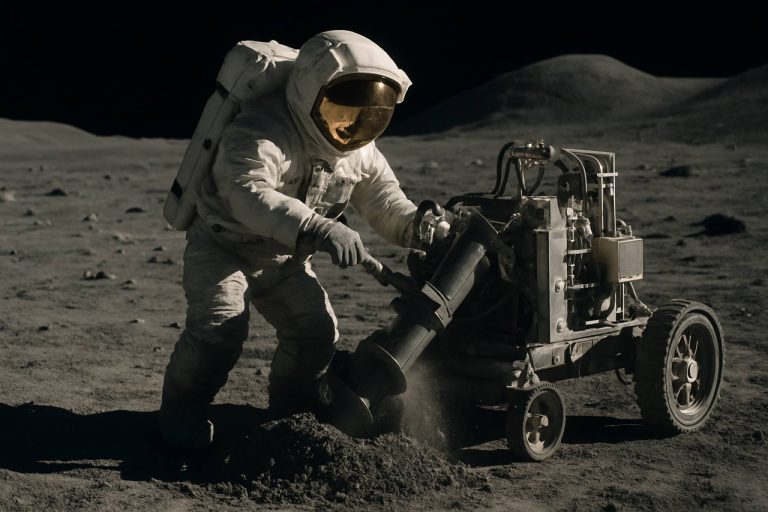

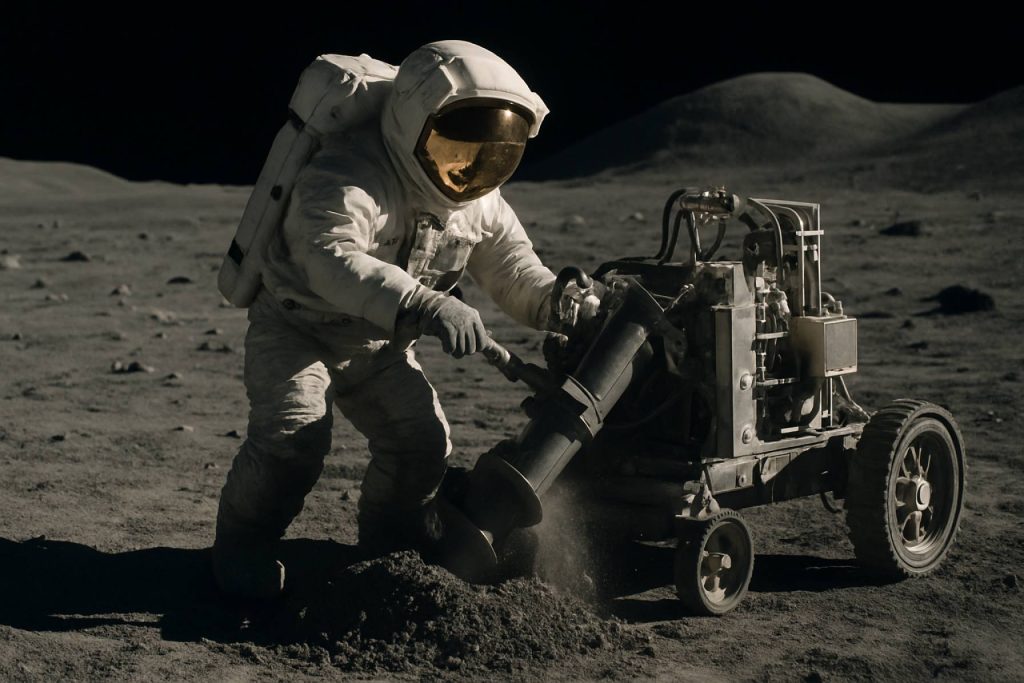

Extraction technologies focus on efficiently collecting and handling regolith in the Moon’s low-gravity, vacuum environment. Robotic systems, such as those developed by NASA and European Space Agency (ESA), are being designed to excavate and transport regolith with minimal dust generation and energy consumption. These systems often incorporate autonomous navigation and teleoperation capabilities to adapt to the challenging lunar terrain.

Processing innovations are centered on separating valuable elements—such as oxygen, silicon, and metals—from the regolith. Techniques like molten regolith electrolysis, pioneered by ESA, enable the extraction of oxygen for life support and propellant, while producing metal alloys as byproducts. Other methods, including carbothermal reduction and hydrogen reduction, are being refined to maximize yield and minimize energy requirements. NASA’s Artemis program is actively testing these processes in simulated lunar environments, aiming for scalable solutions suitable for long-term missions.

Manufacturing technologies leverage the unique properties of lunar regolith to produce construction materials and components directly on the Moon. Additive manufacturing, or 3D printing, using regolith-based feedstocks is a key area of innovation. Organizations like ESA and NASA are developing sintering and binder-jetting techniques to fabricate building blocks, landing pads, and even habitat structures. These methods reduce the need to transport materials from Earth, significantly lowering mission costs and enabling greater autonomy for lunar outposts.

In summary, the 2025 technology landscape for lunar regolith utilization is characterized by integrated systems that combine advanced robotics, efficient resource extraction, and in-situ manufacturing. These innovations are laying the groundwork for sustainable lunar infrastructure and the broader vision of a permanent human presence on the Moon.

Leading Players & Emerging Startups

The field of lunar regolith utilization technologies is rapidly evolving, with established aerospace leaders and innovative startups driving advancements in resource extraction, processing, and application. These technologies are critical for enabling sustainable lunar exploration, in-situ resource utilization (ISRU), and the eventual establishment of lunar habitats.

Among the leading players, National Aeronautics and Space Administration (NASA) has been at the forefront, funding and developing regolith processing systems through programs like Artemis and the Lunar Surface Innovation Initiative. NASA’s partnerships with commercial entities have accelerated the development of technologies for oxygen extraction, 3D printing with regolith, and construction materials.

European Space Agency (ESA) is also a key contributor, supporting projects such as the development of regolith-based 3D printing and oxygen extraction demonstrators. ESA collaborates with European industry and research institutions to advance ISRU capabilities, including the use of microwaves to sinter regolith for building lunar infrastructure.

On the commercial side, Blue Origin is investing in regolith simulant research and ISRU technologies as part of its Blue Moon lunar lander program. Lockheed Martin Corporation and Northrop Grumman Corporation are also developing regolith handling and processing systems for lunar missions, often in collaboration with NASA and international partners.

Emerging startups are playing a pivotal role in pushing the boundaries of lunar regolith utilization. Made In Space, Inc. (now part of Redwire) has demonstrated 3D printing with regolith simulants in microgravity, aiming to enable on-site manufacturing of tools and components. Lunaris and ispace, inc. are developing regolith excavation and processing technologies, targeting both resource extraction and construction applications.

Additionally, Astrobotic Technology, Inc. is working on payload delivery and regolith interaction systems, while Moonwards focuses on open-source lunar infrastructure concepts, including regolith-based construction. These startups often collaborate with space agencies and larger aerospace firms, contributing agility and novel approaches to the sector.

As lunar missions intensify in the coming years, the synergy between established aerospace giants and nimble startups is expected to accelerate the maturation and deployment of lunar regolith utilization technologies, laying the groundwork for a sustainable human presence on the Moon.

Applications: Construction, Life Support, Propellant, and Beyond

Lunar regolith, the fine, powdery soil covering the Moon’s surface, is increasingly recognized as a critical resource for sustainable lunar exploration and settlement. Its utilization spans a range of applications, from construction and life support to propellant production and advanced manufacturing, each leveraging the unique properties and abundance of lunar materials.

In construction, regolith-based technologies are being developed to create durable habitats and infrastructure, reducing the need to transport materials from Earth. Techniques such as sintering, 3D printing, and casting use regolith as a feedstock to fabricate building elements, shielding astronauts from radiation and micrometeorites. NASA and European Space Agency (ESA) have demonstrated regolith simulant-based 3D printing, paving the way for in-situ construction of landing pads, roads, and shelters.

For life support, regolith offers a source of essential elements. Oxygen, constituting up to 45% by weight of lunar regolith in the form of oxides, can be extracted through processes like molten regolith electrolysis or hydrogen reduction. This oxygen is vital for breathable air and water production, as well as for oxidizer in rocket propellants. Indian Space Research Organisation (ISRO) and Japan Aerospace Exploration Agency (JAXA) are actively researching regolith processing for oxygen extraction to support long-duration missions.

Propellant production is another transformative application. By extracting both oxygen and potential hydrogen from regolith and lunar ice, lunar bases could manufacture fuel for surface operations and deep space missions, enabling a sustainable cislunar economy. NASA’s Artemis program and ESA’s ISRU (In-Situ Resource Utilization) initiatives are exploring integrated systems for regolith-derived propellant.

Beyond these core uses, regolith utilization technologies are being investigated for extracting metals (such as iron, aluminum, and titanium) for tools and electronics, and for producing glass and ceramics for scientific instruments. The development of these technologies is central to the vision of a self-sustaining lunar presence, reducing reliance on Earth and enabling new scientific and commercial opportunities on the Moon.

Regulatory and Policy Environment

The regulatory and policy environment for lunar regolith utilization technologies in 2025 is shaped by a complex interplay of international treaties, national legislation, and emerging industry standards. The foundational legal framework is the 1967 Outer Space Treaty, which establishes that celestial bodies, including the Moon, are not subject to national appropriation and must be used for the benefit of all humankind. However, the treaty leaves significant ambiguity regarding the extraction and commercial use of lunar resources, including regolith.

In response to technological advances and growing commercial interest, several countries have enacted national laws to clarify their positions. The National Aeronautics and Space Administration (NASA) and the United States government, through the 2015 Commercial Space Launch Competitiveness Act and subsequent executive orders, have asserted that private entities may own and sell resources extracted from the Moon, provided activities comply with international obligations. Similarly, Luxembourg and the United Arab Emirates have passed legislation supporting private sector rights to space resources.

The United Nations Office for Outer Space Affairs (UNOOSA) continues to facilitate dialogue among member states to address gaps in the current legal regime, particularly regarding resource extraction, environmental protection, and the prevention of harmful interference. The 2020 Artemis Accords, led by NASA and signed by a growing number of nations, establish principles for responsible lunar exploration, including transparency, interoperability, and the peaceful use of space. The Accords specifically address lunar resource utilization, encouraging signatories to inform the international community of their activities and to coordinate to avoid conflicts.

Industry groups such as the Space Foundation and the International Astronautical Federation are working with governments to develop best practices and technical standards for regolith extraction, processing, and use. These efforts aim to ensure safety, sustainability, and equitable access as lunar regolith utilization technologies mature.

Despite these developments, significant regulatory uncertainties remain. Key issues include the definition of property rights, liability for environmental damage, and mechanisms for dispute resolution. As lunar regolith utilization moves from demonstration to commercial scale, ongoing international cooperation and adaptive policy frameworks will be essential to balance innovation, commercial interests, and the collective interests of humanity.

Investment Trends and Funding Landscape

The investment landscape for lunar regolith utilization technologies in 2025 is characterized by a surge in both public and private sector interest, driven by the strategic importance of in-situ resource utilization (ISRU) for sustainable lunar exploration and potential commercial applications. Major space agencies, such as NASA and the European Space Agency (ESA), have significantly increased funding for regolith-related research and demonstration missions. NASA’s Artemis program, for example, has allocated substantial grants to companies developing technologies for extracting oxygen, metals, and water from lunar soil, recognizing these capabilities as critical for long-term lunar presence and future Mars missions.

On the private side, venture capital and corporate investment have accelerated, with startups and established aerospace firms alike pursuing regolith processing, 3D printing, and construction solutions. Companies such as Blue Origin and Lockheed Martin are actively collaborating with government agencies and forming consortia to develop scalable ISRU systems. The Lunar Resources, Inc. and Made In Space (now part of Redwire) have attracted funding rounds focused on regolith-based manufacturing and infrastructure.

Internationally, government-backed initiatives in countries such as Japan and China are also fueling the funding ecosystem. The Japan Aerospace Exploration Agency (JAXA) and the China National Space Administration (CNSA) have announced partnerships with domestic industry to develop regolith processing and utilization technologies, often as part of broader lunar base roadmaps.

In 2025, funding mechanisms are increasingly diverse, including public-private partnerships, innovation challenges, and direct grants. Notably, the NASA Centennial Challenges and ESA’s Discovery & Preparation Programme have issued calls for proposals specifically targeting regolith utilization. This competitive funding environment is fostering rapid prototyping and technology maturation, with a focus on scalability, reliability, and integration with lunar surface operations.

Overall, the investment trends in 2025 reflect a maturing sector, with lunar regolith utilization technologies moving from early-stage research to pilot-scale demonstrations, underpinned by robust funding from both governmental and private sources.

Challenges and Barriers to Adoption

The adoption of lunar regolith utilization technologies faces a range of significant challenges and barriers, both technical and non-technical, that must be addressed to enable sustainable lunar operations. One of the primary technical hurdles is the extreme variability and abrasive nature of lunar regolith itself. Its fine, sharp-edged particles can cause severe wear on mechanical systems, clog filters, and pose health risks to astronauts, complicating the design of excavation, processing, and manufacturing equipment. Additionally, the lack of atmosphere and extreme temperature fluctuations on the Moon require robust, energy-efficient systems that can operate reliably in harsh conditions, increasing engineering complexity and cost.

Another major barrier is the limited availability of in-situ resources for energy and processing. Most proposed regolith utilization technologies, such as oxygen extraction or 3D printing with regolith-based materials, require substantial power inputs. The intermittent nature of solar energy on the lunar surface, especially near the poles or during the two-week lunar night, necessitates advanced energy storage or alternative power generation solutions, which are still under development by organizations like National Aeronautics and Space Administration (NASA) and European Space Agency (ESA).

Logistical and economic barriers also play a significant role. The high cost and complexity of transporting equipment to the Moon, coupled with the need for autonomous or remotely operated systems due to communication delays and limited human presence, make initial deployment and maintenance challenging. Furthermore, the lack of standardized interfaces and protocols for lunar infrastructure, as highlighted by Lunar and Planetary Institute, hinders interoperability and scalability of regolith utilization technologies.

Regulatory and policy uncertainties further complicate adoption. The absence of a comprehensive legal framework governing resource extraction and utilization on the Moon, as discussed by United Nations Office for Outer Space Affairs (UNOOSA), creates ambiguity around property rights, environmental protection, and international collaboration. This uncertainty can deter private investment and slow the development of commercial lunar regolith utilization ventures.

Addressing these challenges will require coordinated efforts in technology development, international policy-making, and the establishment of shared standards and best practices. Only through overcoming these barriers can lunar regolith utilization technologies become a cornerstone of sustainable lunar exploration and development.

Future Outlook: Roadmap to 2030 and Beyond

The future outlook for lunar regolith utilization technologies is shaped by ambitious international and commercial plans for sustained lunar presence and resource exploitation. By 2030, the roadmap envisions a transition from experimental demonstrations to operational systems that can support lunar infrastructure, habitats, and in-situ resource utilization (ISRU) for both robotic and crewed missions.

Key milestones anticipated by 2030 include the deployment of pilot-scale regolith processing units capable of extracting oxygen, metals, and building materials directly on the lunar surface. Agencies such as NASA and European Space Agency (ESA) are advancing ISRU demonstrators, with NASA’s Artemis program targeting the demonstration of oxygen extraction from regolith and the production of construction materials for landing pads and habitats. The Japan Aerospace Exploration Agency (JAXA) and Indian Space Research Organisation (ISRO) are also exploring regolith-based technologies for future lunar missions.

Commercial entities are expected to play a growing role, with companies like Blue Origin and Astrobotic Technology, Inc. developing payloads and landers designed to deliver and test ISRU hardware. The maturation of additive manufacturing techniques using regolith simulants is paving the way for 3D printing of lunar infrastructure, reducing the need to transport bulky materials from Earth.

Beyond 2030, the focus will likely shift to scaling up these technologies for continuous operation, supporting lunar bases, and enabling the extraction of volatiles and metals for use in life support, fuel production, and construction. International collaboration, standardization of regolith processing methods, and the development of lunar supply chains are expected to accelerate progress. The Lunar and Planetary Institute and International Lunar Exploration Working Group (ILEWG) are fostering global partnerships to address technical, legal, and policy challenges.

In summary, the roadmap to 2030 and beyond for lunar regolith utilization technologies is marked by a shift from proof-of-concept to operational deployment, with increasing collaboration between government agencies and private industry. These advancements are critical for establishing a sustainable human presence on the Moon and laying the groundwork for future deep space exploration.

Sources & References

- NASA

- European Space Agency (ESA)

- Blue Origin

- ispace, inc.

- Japan Aerospace Exploration Agency (JAXA)

- Lockheed Martin Corporation

- Northrop Grumman Corporation

- Made In Space, Inc.

- Lunaris

- Astrobotic Technology, Inc.

- Indian Space Research Organisation

- United Nations Office for Outer Space Affairs (UNOOSA)

- Lunar Resources, Inc.