Table of Contents

- Executive Summary: 2025 Market Inflection Point

- Technology Primer: What Are Mixed Domain X-ray Metamaterials?

- Key Innovations in Fabrication Methods (2024–2028)

- Global Market Size & Forecasts Through 2030

- Major Industry Players and Emerging Startups

- Applications: Medical Imaging, Security, and Beyond

- Regulatory Landscape and Standards (IEEE, ISO)

- Supply Chain and Materials Sourcing Trends

- Investment, M&A, and Funding Hotspots

- Future Outlook: Disruptive Potential and Next-Gen Use Cases

- Sources & References

Executive Summary: 2025 Market Inflection Point

The market for mixed domain X-ray metamaterial fabrication is poised for a significant inflection point in 2025, driven by rapid advancements in material science, precision nanofabrication techniques, and increasing commercial demand for next-generation X-ray optics and imaging systems. Mixed domain metamaterials—engineered structures combining multiple physical domains (e.g., electromagnetic, acoustic, and thermal)—are now being actively developed for X-ray applications, with the goal of achieving unprecedented control over X-ray propagation, filtration, and focusing.

Within the past year, several key industry players have announced successful demonstration and scaling of fabrication techniques tailored for the stringent requirements of X-ray wavelengths (sub-nanometer to nanometer scale). Notably, Carl Zeiss AG has expanded their X-ray optics portfolio to include multilayer and diffractive elements manufactured using atomic layer deposition and advanced lithography, enabling new classes of meta-optics with tailored spectral responses. Oxford Instruments has also reported advances in focused ion beam (FIB) and electron beam lithography for mixed domain structures, supporting the trend towards ever finer feature sizes and higher aspect ratios necessary for X-ray metamaterials.

Concurrently, the semiconductor industry’s push toward sub-10 nm process nodes is accelerating the adoption of X-ray metamaterials in inspection and metrology tools, with ASML Holding NV integrating custom-fabricated metamaterial components into its extreme ultraviolet (EUV) lithography systems. These collaborations are facilitating cost reductions and scalability, which are essential for broader commercial rollouts.

In the research sector, government-backed facilities such as the European Synchrotron Radiation Facility and SLAC National Accelerator Laboratory are transitioning from proof-of-concept demonstrations to pilot-scale production of mixed domain X-ray metamaterials, supporting both scientific instrumentation and nascent medical imaging applications.

Looking ahead, 2025 is expected to mark the beginning of wider commercialization, as high-precision fabrication equipment becomes more accessible and design libraries for mixed domain X-ray metamaterials mature. Industry analysts anticipate that these developments will enable not only more efficient X-ray lenses and filters, but also pave the way for disruptive advances in X-ray security screening, non-destructive testing, and compact X-ray sources for laboratory and clinical environments. The trajectory suggests strong growth potential through 2027 as supply chains stabilize and application-specific metamaterial designs reach market maturity.

Technology Primer: What Are Mixed Domain X-ray Metamaterials?

Mixed domain X-ray metamaterials are engineered composites designed to manipulate X-ray waves in ways not possible with natural materials. Their fabrication involves integrating structures and phases that interact with both the electric and magnetic components of X-ray electromagnetic fields across multiple spatial scales. The unique challenge of X-ray metamaterial fabrication lies in achieving precise patterning and assembly at nanometer—and even sub-nanometer—scales, given the extremely short wavelengths of hard X-rays (0.01–10 nm). This section reviews recent technological advances, notable industry players, and the near-term outlook for mixed domain X-ray metamaterial fabrication as of 2025.

The field has witnessed significant progress due to the convergence of nanofabrication techniques, such as electron beam lithography (EBL), focused ion beam (FIB) milling, and advanced atomic layer deposition (ALD). These methods are now routinely used to produce multilayer X-ray optics and metamaterials with feature sizes well below 10 nm. For instance, Carl Zeiss AG and JEOL Ltd. supply state-of-the-art FIB systems that have been adopted by research labs and manufacturers for prototyping and small-batch fabrication of complex X-ray meta-structures. Additionally, Oxford Instruments and Veeco Instruments Inc. are advancing ALD systems to deposit ultrathin, conformal films essential for multilayer X-ray metamaterial stacks.

A key 2025 milestone is the demonstration of large-area, low-defect X-ray metasurfaces using nanoimprint lithography by SUSS MicroTec SE, enabling scalable production beyond small research samples. In parallel, Rigaku Corporation and Xenocs have begun integrating metamaterial-based elements into commercial X-ray optics, facilitating the transition from laboratory demonstration to application in synchrotron beamlines and analytical instrumentation.

Looking forward, hybrid fabrication approaches combining top-down lithography with bottom-up self-assembly and template-directed growth are expected to accelerate the development and availability of multifunctional X-ray metamaterials. Companies like ASML Holding NV are pioneering advanced EUV lithography that, while initially developed for semiconductor manufacturing, is being adapted for X-ray regime patterning at resolutions below 5 nm. Collaborative efforts between equipment makers and research institutions are likely to further reduce costs and increase throughput, addressing current bottlenecks in scalability and uniformity.

In summary, 2025 marks a turning point for X-ray metamaterial fabrication, with commercial-scale tools and processes emerging to support both scientific and industrial applications. Continued innovation in nanofabrication and materials integration is poised to unlock new X-ray optics and devices with unprecedented performance, heralding transformative impacts across imaging, spectroscopy, and quantum X-ray technologies.

Key Innovations in Fabrication Methods (2024–2028)

The fabrication of mixed domain X-ray metamaterials is experiencing rapid innovation, enabled by advances in both material science and micro/nanofabrication techniques. Mixed domain metamaterials—engineered structures that combine multiple physical domains such as dielectric, metallic, and even magnetic constituents—are at the forefront of achieving unprecedented control over X-ray propagation, absorption, and phase manipulation. As of 2025, the field is witnessing a convergence of approaches from synchrotron science, semiconductor manufacturing, and advanced lithography, all directed toward scalable and reproducible production.

One notable trend is the adaptation of atomic layer deposition (ALD) and focused ion beam (FIB) milling to fabricate multilayered and heterostructured metamaterials with nanometric precision. Oxford Instruments has reported advances in FIB-SEM platforms that allow for the direct patterning of sub-20 nm features, critical for X-ray wavelengths. Meanwhile, ALD processes pioneered by Beneq are being utilized to deposit conformal, ultra-thin layers of high-Z materials (e.g., tungsten, hafnium oxide) onto complex 3D scaffolds, which is vital for constructing high-efficiency X-ray diffractive optics.

In the realm of large-area and scalable fabrication, Toppan Inc. has demonstrated nanoimprint lithography techniques capable of producing sub-50 nm periodic structures over wafer-scale substrates. This development is pivotal for mass production of mixed domain metamaterials, facilitating their integration into X-ray imaging systems and laboratory-based optics.

Another emerging direction is the use of hybrid organic-inorganic resists and direct laser writing, as implemented by Nanoscribe GmbH. Their two-photon polymerization technology enables the fabrication of intricate 3D architectures that can subsequently be metallized or functionalized for X-ray operation, bridging the gap between design complexity and manufacturability.

Outlook for the next few years (2025–2028) suggests that mixed domain X-ray metamaterial fabrication will continue to benefit from cross-disciplinary advances, particularly in additive manufacturing and self-assembly. The integration of AI-driven process control and in-situ metrology, as explored by Carl Zeiss AG, is expected to further enhance yield and device performance. These innovations collectively are poised to accelerate the deployment of next-generation X-ray optics and detectors for applications in medical diagnostics, lithography, and materials science.

Global Market Size & Forecasts Through 2030

The global market for mixed domain X-ray metamaterial fabrication is positioned for notable growth as advancements in nanofabrication, materials science, and X-ray applications converge. Mixed domain metamaterials—engineered structures that simultaneously exploit multiple physical domains (e.g., electromagnetic, acoustic, mechanical)—are transforming X-ray optics, detection, and imaging by enabling unprecedented control over X-ray propagation, absorption, and filtering. As of 2025, the industry is experiencing increased investments, with a focus on scaling fabrication processes and integrating metamaterials into commercial X-ray systems.

Current market leaders such as Carl Zeiss AG and Rigaku Corporation are expanding their portfolios to include advanced metamaterial-based X-ray optics, targeting applications in medical imaging, semiconductor inspection, and materials research. For example, Carl Zeiss AG has reported ongoing development of diffractive and refractive X-ray optics leveraging nanofabricated metamaterial structures, aiming to enhance resolution and efficiency in next-generation X-ray microscopy platforms.

In Asia, Hitachi High-Tech Corporation and Olympus Corporation have announced investments in advanced lithography and atomic layer deposition (ALD) tools for fabricating mixed domain metamaterials, responding to a growing demand from semiconductor manufacturers for ultra-precise X-ray inspection tools. Meanwhile, Bruker Corporation is collaborating with industrial and academic partners to accelerate the commercialization of multilayer and nanostructured X-ray optics.

The sector’s growth is evident in expanding pilot production lines, particularly in Europe and North America, where Electro Scan Inc. and ANSYS, Inc. are supporting the development of simulation and quality control tools tailored for metamaterial-based X-ray systems. These capabilities are critical for scaling up from laboratory prototypes to mass production with tight tolerances and reliability.

Looking toward 2030, the global market for mixed domain X-ray metamaterial fabrication is projected to grow at a compound annual growth rate (CAGR) exceeding 15%, driven by strong adoption in medical diagnostics, non-destructive testing, and semiconductor metrology. Key challenges remain, including cost-effective large-area fabrication and integration with existing X-ray platforms. However, with major industry stakeholders investing in R&D and manufacturing capacity, the outlook for the sector is robust, with expectations that mixed domain metamaterials will become standard components in high-performance X-ray systems within the next few years.

Major Industry Players and Emerging Startups

The field of mixed domain X-ray metamaterial fabrication is witnessing notable activity among established industry leaders and a growing cohort of innovative startups. As of 2025, several companies are advancing the state-of-the-art in X-ray metamaterial design and manufacturing, focusing on applications ranging from medical imaging to synchrotron facilities and advanced non-destructive testing.

- ZEISS: Renowned for its precision optics, Carl Zeiss AG has expanded its efforts in developing nano-fabricated X-ray optics, leveraging advanced lithography and etching techniques. Their collaborations with research institutions facilitate the integration of mixed domain metamaterials—structures that combine functionalities such as phase and amplitude modulation—to enhance X-ray microscopy and tomography.

- Carl Zeiss SMT: As a subsidiary specializing in semiconductor manufacturing technology, Carl Zeiss SMT is investing in the fabrication of multilayer X-ray mirrors and zone plates with unprecedented spatial precision, supporting both industrial and scientific end-users.

- Applied Materials: Applied Materials is pursuing scalable nanofabrication platforms for X-ray metamaterials, focusing on combining traditional semiconductor processing with new materials to create tunable X-ray lenses and filters for both medical and industrial applications.

- Rigaku Corporation: Rigaku is an established manufacturer of X-ray instrumentation and is now developing next-generation metamaterial-based optics to improve X-ray diffraction and imaging systems, aiming to reduce system size while increasing resolution and contrast.

- Emerging Startups: Startups such as Xnext are gaining attention for their novel approaches to integrating mixed domain metamaterials into real-time X-ray inspection systems, particularly in security and quality control sectors. Their proprietary technologies combine spectral and spatial filtering at the detector level, enabled by precision-fabricated metamaterials.

- Industry-Academic Collaborations: Organizations like European Synchrotron Radiation Facility (ESRF) and Paul Scherrer Institute are partnering with both established companies and startups to scale up the fabrication of hybrid X-ray metamaterials, aiming to push forward capabilities in phase contrast imaging and high-resolution spectroscopy.

Looking forward, these players are expected to accelerate the commercialization of mixed domain X-ray metamaterials, driven by growing demand in healthcare, semiconductor inspection, and advanced materials analysis. Continuous improvements in nanofabrication and material science are likely to foster greater performance, scalability, and new application domains over the next few years.

Applications: Medical Imaging, Security, and Beyond

The fabrication of mixed domain X-ray metamaterials—engineered composites exhibiting tailored electromagnetic responses in the X-ray range—has gained considerable momentum in 2025, driven by pressing demands in medical imaging, security screening, and advanced industrial inspection. These metamaterials, which combine multiple material domains (such as dielectric, metallic, and semiconductor inclusions), enable functionalities unattainable with conventional materials, such as negative refractive indices and enhanced absorption or scattering control at nanometer scales.

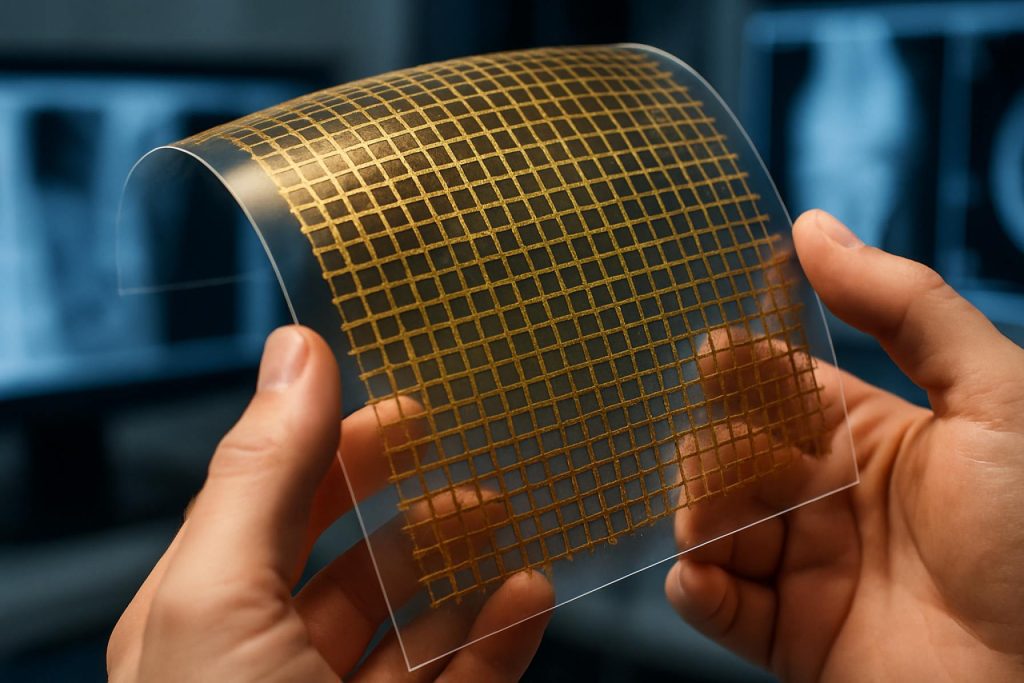

Recent advancements have centered on integrating nanoscale patterning techniques with scalable manufacturing, aiming to transition from laboratory demonstrations to real-world deployment. Electron-beam lithography, focused ion beam milling, and nanoimprint lithography remain central to prototyping, but for large-area applications, industry is increasingly turning to methods like atomic layer deposition (ALD) and roll-to-roll nanoimprint processes. Companies such as Oxford Instruments are actively developing ALD systems tailored for complex multilayer X-ray metamaterials, supporting the precise layer control required for mixed domain architectures.

Material selection is another focal point. The ability to combine high-Z elements such as tungsten or gold with low-Z dielectrics or polymers allows for fine-tuning of X-ray attenuation and scattering properties, vital for applications like computed tomography (CT) contrast agents and anti-counterfeiting markers. Goodfellow and Kurt J. Lesker Company are supplying a growing catalog of nanostructured metals and composite targets, supporting research and small-scale production.

In medical imaging, mixed domain metamaterials are enabling the design of novel X-ray optics—such as phase contrast lenses and multilayer Bragg reflectors—that offer higher resolution at reduced doses. Collaborations between device manufacturers and research institutions, including those facilitated by Carl Zeiss AG, are accelerating the integration of metamaterial-based components into next-generation X-ray microscopes and mammography systems.

For security, the ability to tailor X-ray metamaterial signatures is essential for developing covert tags and encoding information within objects, providing a new layer of authentication and traceability. Partnerships with companies like Smiths Detection are exploring how mixed domain metamaterials can be embedded in packaging or identification cards for enhanced security screening.

Looking ahead, the outlook for mixed domain X-ray metamaterial fabrication is robust. As fabrication costs decrease and material libraries expand, broader adoption across medical, security, and industrial sectors is anticipated. The next few years will likely see increased standardization of fabrication protocols and the emergence of dedicated foundry services for X-ray metamaterials, enabling rapid prototyping and customization to specific application requirements.

Regulatory Landscape and Standards (IEEE, ISO)

The regulatory landscape governing mixed domain X-ray metamaterial fabrication is rapidly evolving, reflecting both the emergence of next-generation materials and the growing integration of these metamaterials into critical technologies such as advanced imaging, security screening, and photonic devices. As of 2025, the sector faces a complex patchwork of standards and guidelines, with principal oversight stemming from international bodies like the International Organization for Standardization (ISO) and technical societies such as the Institute of Electrical and Electronics Engineers (IEEE).

ISO continues to play a pivotal role in setting materials and testing standards relevant to X-ray metamaterials, particularly through its technical committees on nanotechnologies (ISO/TC 229) and advanced materials (ISO/TC 261). Notably, ISO has developed guidance for nanostructure characterization and performance testing, which are increasingly referenced in the prototyping and quality assurance stages for mixed domain metamaterials. As fabrication methods such as atomic layer deposition, focused ion beam milling, and nanoimprint lithography become integral to X-ray metamaterial production, the applicability of existing ISO standards is being re-examined and, in some cases, expanded to address the unique challenges of multi-material, multi-scale architectures (International Organization for Standardization).

On the electrical and photonic engineering front, the IEEE has ramped up activities in standardizing the characterization and interoperability of metamaterials, with working groups under the IEEE Nanotechnology Council and the IEEE Photonics Society addressing measurement protocols, safety, and performance benchmarks for novel X-ray-responsive structures. In 2024, the IEEE released preliminary guidelines for electromagnetic performance evaluation of hybrid metamaterials, with further updates anticipated in 2025 to specifically include X-ray regimes (Institute of Electrical and Electronics Engineers).

Regulatory focus has also sharpened on health and environmental safety, given the nanoscale composition of these materials and their potential for bioaccumulation or toxicity. ISO’s ongoing efforts, including the ISO/TR 16197:2020 guidance on nanomaterial safety, are directly informing best practices for waste management and worker protection in metamaterial fabrication facilities.

Looking ahead, stakeholders anticipate a convergence of ISO and IEEE frameworks, aiming to harmonize definitions and methodologies across fabrication, testing, and application contexts. Industry consortia and leading manufacturers are increasingly participating in standards development, ensuring that regulatory evolution keeps pace with fabrication innovations. The next few years are expected to see greater specificity in guidelines for traceability, reproducibility, and lifecycle assessment of mixed domain X-ray metamaterials, bolstering both commercialization and cross-border collaboration.

Supply Chain and Materials Sourcing Trends

The supply chain and materials sourcing landscape for mixed domain X-ray metamaterial fabrication is rapidly evolving as the field transitions from laboratory-scale prototypes to larger pre-commercial and early commercial deployments. In 2025, leading suppliers of advanced materials are reinforcing upstream capabilities to address rising demand for high-purity metals, engineered multilayers, and nanostructured substrates critical to X-ray metamaterial performance.

Key players in the X-ray optics and components sector, such as Carl Zeiss AG and Oxford Instruments, are actively securing specialized thin-film deposition sources, precision etching chemicals, and rare earth elements. Recent investments in sputtering targets, atomic layer deposition (ALD) precursors, and electron-beam evaporation materials illustrate the sector’s focus on reproducibility and scalability. In parallel, new supply partnerships have been established with substrate manufacturers for single-crystal silicon, silicon nitride, and synthetic diamond—materials chosen for their low X-ray absorption and compatibility with high-aspect-ratio nanofabrication.

Supply chain resilience has become a priority in response to global disruptions and geopolitical tensions that impact critical material flows. For instance, Sumitomo Chemical Co., Ltd. has expanded its portfolio of ultra-high-purity chemicals and advanced ceramics for the photonics and X-ray markets, while ULVAC, Inc. is scaling up production of specialty targets for X-ray metamaterials. These moves are aimed at reducing reliance on single-source vendors and ensuring consistent quality and traceability for demanding end users in medical imaging, semiconductor metrology, and synchrotron research.

In the next few years, greater emphasis will be placed on sustainable sourcing and life-cycle management for critical elements such as tantalum, hafnium, and rare earths, which are integral to high-performance X-ray metamaterial layers. Industry organizations, including SEMI, are advocating for transparent sourcing standards and recycling initiatives to mitigate supply risks and environmental impact. Additionally, advanced metrology systems provided by companies like Bruker Corporation are being integrated into quality assurance workflows to certify the atomic-scale uniformity of sourced materials.

Overall, the outlook through 2025 and beyond points to continued investment in robust, diversified supply chains and a shift towards materials stewardship, with leading manufacturers and suppliers closely aligning sourcing strategies to the stringent and evolving requirements of mixed domain X-ray metamaterial fabrication.

Investment, M&A, and Funding Hotspots

Mixed domain X-ray metamaterial fabrication has emerged as a focal point for investment and strategic consolidation, driven by breakthroughs in advanced imaging, medical diagnostics, and security applications. As of 2025, the sector is witnessing a surge in capital inflows, with both established industry leaders and agile startups vying for technological dominance.

One of the most significant investment hotspots is the development of nanoscale fabrication techniques that enable the precise engineering of X-ray metamaterials with tailored optical properties. Companies such as Carl Zeiss Microscopy and Thermo Fisher Scientific are expanding their R&D portfolios to include electron beam lithography and focused ion beam methods, critical for producing intricate mixed-domain structures. These investments are supported by strategic partnerships with academic institutions and government laboratories, fostering a pipeline of innovation and workforce expertise.

Mergers and acquisitions (M&A) activity is accelerating, particularly as large imaging and material science conglomerates seek to vertically integrate novel X-ray metamaterial capabilities. For example, Bruker Corporation has signaled interest in acquiring startups specializing in hybrid organic-inorganic X-ray metamaterial platforms, aiming to enhance its portfolio in high-resolution X-ray imaging. The acquisition trend is also evident in the security sector, where companies like Smiths Detection are actively scouting for innovative metamaterial-based X-ray sources and detectors to reinforce their market position in airport and border security.

Venture capital and government funding are increasingly directed toward companies that demonstrate scalable fabrication processes and robust integration with existing X-ray imaging systems. Notably, the U.S. Department of Energy has announced funding opportunities for collaborative projects focused on advanced metamaterial manufacturing, attracting attention from industry players and research consortia. Startups such as Nanoscribe GmbH are also drawing investment for their two-photon polymerization technologies, which offer new avenues for fabricating complex three-dimensional X-ray metamaterial architectures.

Looking ahead to the next few years, investment momentum is expected to persist as the demand for higher sensitivity, lower dose, and multi-modal X-ray imaging grows across medical, industrial, and security domains. As fabrication technologies mature and intellectual property portfolios expand, the sector is likely to witness further consolidation and the emergence of new funding hotspots, particularly in Asia and North America, where regional governments and tech giants are ramping up support for advanced material innovation.

Future Outlook: Disruptive Potential and Next-Gen Use Cases

The fabrication of mixed domain X-ray metamaterials—engineered structures that manipulate X-rays through combined control over electric, magnetic, and mechanical responses—is poised for significant breakthroughs in 2025 and the next few years. This field is driven by advances in nanofabrication, materials science, and a growing demand for high-performance optics in medical imaging, security, and quantum technologies.

One of the key developments is the increasing deployment of hybrid fabrication techniques that combine top-down lithography with bottom-up self-assembly. For instance, companies such as Carl Zeiss AG are pushing the envelope with focused ion beam and electron beam lithography systems tailored for sub-10 nm feature sizes, critical for X-ray wavelengths. In parallel, Oxford Instruments is advancing plasma etching and atomic layer deposition methods to enable high aspect ratio nanostructures with the material purity and uniformity required for X-ray manipulation.

Material innovation is another driver. The integration of high-index materials (such as hafnium oxide and tantalum-based compounds) with low-loss polymers is being facilitated by suppliers like Merck KGaA, who provide specialty materials for nanofabrication. These materials support the dual control of electromagnetic and mechanical properties, crucial for mixed domain metamaterial function. Recent collaborations between material providers and X-ray optics manufacturers are expected to accelerate the translation from laboratory-scale prototypes to scalable, industrial-grade components.

A particularly disruptive trend is the convergence of X-ray mixed domain metamaterials with MEMS (Micro-Electro-Mechanical Systems) platforms. Leading research institutes and industry partners, including IMTEK – University of Freiburg, are demonstrating tunable X-ray lenses and modulators that leverage mechanical actuation at the nanoscale. These systems promise real-time adaptability, opening doors for next-generation imaging systems and dynamic beam shaping in synchrotron and free-electron laser facilities.

Looking forward, the sector anticipates rapid commercialization, especially in security screening and medical diagnostics. The adoption of mixed domain metamaterials in compact, high-resolution imaging systems is likely to be catalyzed by end-users such as Siemens Healthineers and Canon Medical Systems, who are actively exploring partnerships and pilot deployments. The next few years will likely see a feedback loop between application-driven demand and fabrication innovation, underpinning the disruptive potential of X-ray metamaterials in multiple domains.

Sources & References

- Carl Zeiss AG

- Oxford Instruments

- ASML Holding NV

- European Synchrotron Radiation Facility

- JEOL Ltd.

- Veeco Instruments Inc.

- SUSS MicroTec SE

- Rigaku Corporation

- Xenocs

- Beneq

- Toppan Inc.

- Nanoscribe GmbH

- Hitachi High-Tech Corporation

- Olympus Corporation

- Bruker Corporation

- Electro Scan Inc.

- Paul Scherrer Institute

- Goodfellow

- Kurt J. Lesker Company

- Smiths Detection

- International Organization for Standardization

- Institute of Electrical and Electronics Engineers

- Oxford Instruments

- Sumitomo Chemical Co., Ltd.

- ULVAC, Inc.

- Thermo Fisher Scientific

- IMTEK – University of Freiburg

- Siemens Healthineers

- Canon Medical Systems