Table of Contents

- Executive Summary: 2025 Market Outlook and Key Trends

- Major Nonlinear Optical Crystals: Materials and Innovations

- Cutting-Edge Fabrication Techniques Transforming Production

- Leading Companies and R&D Initiatives (e.g., cztcrystals.com, thorlabs.com, coherent.com)

- Growth Drivers: Telecom, Quantum, Medical, and Defense Applications

- Regional Analysis: Asia-Pacific, North America, Europe, and Emerging Markets

- Market Forecast 2025-2030: Revenue, Volume, and Demand Trends

- Supply Chain and Quality Control: Challenges and Solutions

- Sustainability and Green Manufacturing Initiatives

- Future Outlook: Next-Gen Materials and Strategic Roadmaps

- Sources & References

Executive Summary: 2025 Market Outlook and Key Trends

The nonlinear optical (NLO) crystals fabrication sector is entering 2025 with strong momentum, driven by the rapid expansion of photonics, quantum technologies, and ultrafast laser applications. The demand for high-quality NLO crystals—including lithium niobate (LiNbO₃), beta barium borate (BBO), potassium titanyl phosphate (KTP), and periodically poled materials—is accelerating in tandem with innovation in telecommunications, medical imaging, and advanced manufacturing.

Leading manufacturers such as Gooch & Housego, Crylink, and CASTON continue to invest in advanced growth techniques like Czochralski, hydrothermal, and top-seeded solution growth to improve crystal purity, size, and homogeneity. These companies are scaling up production capabilities to address the increasing need for both traditional and engineered NLO crystals. Notably, the adoption of periodically poled crystals—particularly periodically poled lithium niobate (PPLN)—is surging due to their efficiency in wavelength conversion and their critical role in next-generation quantum photonics platforms.

2025 sees heightened collaboration between research institutes and commercial suppliers to accelerate the transfer of novel fabrication methods, such as laser-assisted poling and low-defect flux growth. This trend is particularly evident in the integration of NLO crystals with silicon photonics and the development of quasi-phase-matched structures to support compact, chip-scale devices. Market leaders are also focusing on automation and tighter process control, with companies like CASTON and Crylink implementing real-time monitoring and feedback systems to boost yield and reduce defect rates.

On the supply chain front, geopolitical factors and the push toward regional self-sufficiency are leading to diversification of production bases and investments in local crystal growth facilities. This is expected to mitigate risks of material shortages and stabilize pricing in the near term.

Looking forward, the outlook for NLO crystal fabrication remains robust through 2025 and beyond. The sector is poised for continued growth, underpinned by advances in crystal engineering and increased demand from quantum communication, LIDAR, and frequency comb technologies. With ongoing improvements in reproducibility, scalability, and integration, manufacturers are well-positioned to deliver the next generation of high-performance nonlinear optical materials, supporting the evolving needs of the global photonics industry.

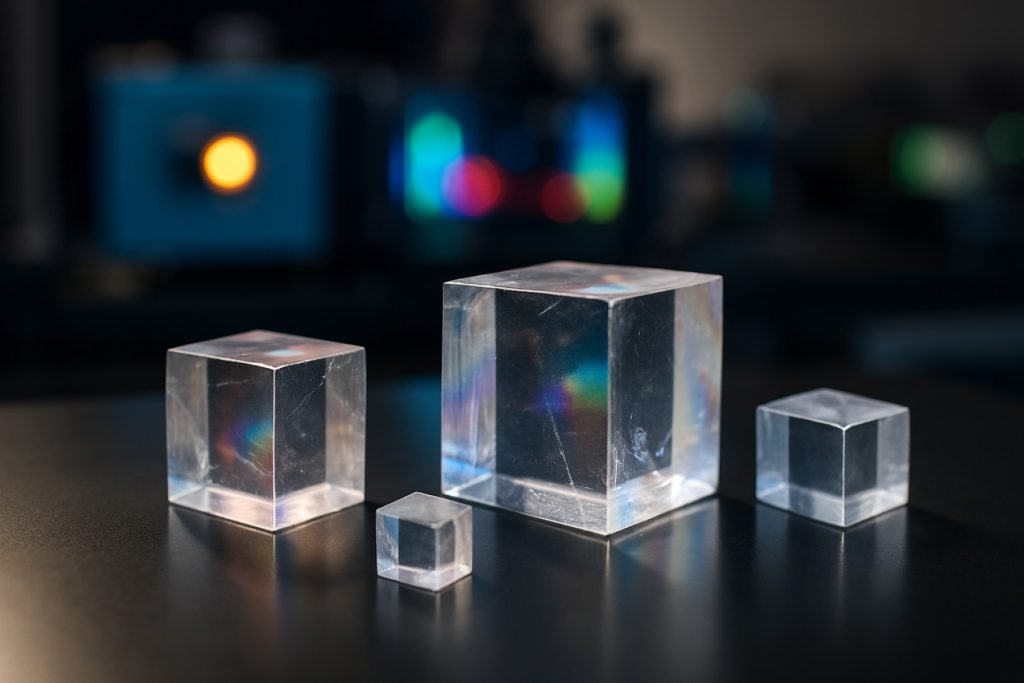

Major Nonlinear Optical Crystals: Materials and Innovations

Fabrication techniques for nonlinear optical (NLO) crystals are advancing rapidly in 2025, driven by escalating demand from sectors such as telecommunications, quantum computing, and high-power laser systems. The primary materials in focus include lithium niobate (LiNbO3), potassium titanyl phosphate (KTP), beta barium borate (BBO), and periodically poled materials, each requiring tailored growth and processing methods to optimize their nonlinear properties and optical quality.

Crystal growth remains foundational, with the Czochralski and flux methods being the most prevalent for producing bulk NLO crystals. Companies such as CASTLE STONE and CRYLINK are actively manufacturing high-purity lithium niobate and BBO crystals, emphasizing precise temperature control and compositional uniformity to minimize defects and inclusions. In 2025, there is a notable shift toward scaling up crystal boules while maintaining low absorption and scattering losses, critical for high-power laser applications.

For applications requiring quasi-phase matching—such as frequency doubling in telecom wavelengths—periodically poled crystals have become central. The fabrication of periodically poled lithium niobate (PPLN) and periodically poled potassium titanyl phosphate (PPKTP) now employs high-voltage electric field poling with photolithographically defined electrodes, achieving domain periods below 5 μm with improved reproducibility. Shin-Etsu Chemical and Coherent Corp. are recognized for advancing the mass production of PPLN wafers with uniform domain structures, enabling integration into photonic circuits and quantum light sources.

Thin film and waveguide fabrication are also expanding. Ion-slicing and wafer bonding techniques, pioneered by companies like NanoLN, are being scaled to produce high-quality thin-film lithium niobate on insulator (LNOI) substrates. These substrates are critical for the next generation of photonic integrated circuits, supporting ultra-compact and efficient frequency converters and modulators. In parallel, femtosecond laser writing is being refined to create 3D waveguides in BBO and KTP, broadening the design flexibility for integrated nonlinear devices.

Looking ahead to the next few years, further automation of crystal growth, in-situ defect monitoring, and environmental controls are expected to increase yield rates and reproducibility. Industry players are investing in research to reduce fabrication costs while pushing the performance boundaries—particularly for scalable, chip-compatible NLO crystals for quantum and data center applications. Close collaboration between material suppliers and device manufacturers will likely accelerate the adoption of next-generation nonlinear crystals in emerging photonic platforms.

Cutting-Edge Fabrication Techniques Transforming Production

The fabrication of nonlinear optical (NLO) crystals is experiencing a significant transformation in 2025, driven by advances in material science, precision engineering, and process automation. These developments are crucial for meeting the growing demand for high-performance crystals in applications such as quantum optics, telecommunications, and high-power laser systems.

A primary trend is the refinement of crystal growth techniques. Companies specializing in NLO materials are increasingly leveraging advanced methods like top-seeded solution growth (TSSG), Czochralski pulling, and hydrothermal synthesis to achieve unprecedented purity and uniformity. For example, the Czochralski process, known for its ability to yield large single crystals, is being optimized through improved temperature control and real-time monitoring, ensuring superior optical homogeneity and reducing defect density. Leading producers such as CAST Photonics and Crylink are at the forefront of these innovations, particularly in the fabrication of potassium titanyl phosphate (KTP), beta-barium borate (BBO), and lithium triborate (LBO) crystals.

Automated crystal cutting and surface finishing are also being revolutionized with the integration of computer-controlled laser machining and chemical-mechanical polishing (CMP). These approaches enable the production of complex crystal geometries and ultra-smooth surfaces required for efficient frequency conversion and minimal optical loss. The adoption of precision metrology tools, such as interferometric surface profilers and X-ray diffraction systems, allows for real-time feedback during the fabrication process, further raising the standards for quality and consistency.

Another key development is the scaling-up of production capacity to address the needs of burgeoning sectors like quantum computing and next-generation LiDAR. Companies such as CAST Photonics and Fujicrystal are investing in modular, automated production lines capable of handling larger crystal boules and batch processing, thus reducing lead times and enhancing throughput without compromising material quality.

Looking ahead to the next few years, the outlook for NLO crystal fabrication is marked by the convergence of AI-driven process optimization and sustainable manufacturing practices. The adoption of machine learning algorithms for process control is expected to further minimize defects and improve yield. Simultaneously, there is a growing industry focus on eco-friendly solvents and energy-efficient growth chambers, reflecting broader trends in green photonics.

In summary, state-of-the-art fabrication techniques are rapidly reshaping the NLO crystal landscape, enabling higher quality, greater scalability, and improved performance to satisfy the evolving requirements of advanced photonic technologies.

Leading Companies and R&D Initiatives (e.g., cztcrystals.com, thorlabs.com, coherent.com)

The fabrication of nonlinear optical (NLO) crystals is a cornerstone of modern photonics, with advances in this sector enabling everything from telecommunications and quantum computing to high-efficiency frequency conversion. As of 2025, industry leadership is demonstrated by a handful of companies with established expertise and ongoing R&D investments, focusing on both new materials and improvements in crystal growth and quality assurance.

Among the most prominent is Thorlabs, which continues to expand its portfolio of NLO crystals, such as BBO, LBO, and KTP. Their fabrication capabilities focus on both standard and custom solutions for research and industrial clients, with ongoing refinements in crystal purity and damage threshold. Thorlabs’ investments in advanced crystal growth techniques aim to reduce inclusions and optical defects, directly addressing the demand for higher performance in ultrafast and high-power laser applications.

Another key player, Coherent, maintains a significant role in advancing NLO crystal technology, with a particular emphasis on large-aperture and high-uniformity crystals for use in laser systems. Their R&D activities in 2025 are geared toward optimizing flux growth processes and introducing new doping strategies to enhance nonlinear coefficients and phase-matching bandwidths. Coherent’s vertically integrated supply chain also facilitates rapid prototyping and commercialization of emerging NLO materials.

Specialized companies like CZT Crystals are actively innovating in the fabrication of niche and challenging materials such as ZnTe, GaSe, and CdTe crystals. They report advances in multi-step purification and Bridgman growth methods, targeting applications in terahertz generation and mid-infrared spectroscopy. Their 2025 R&D agenda includes collaborations with academic partners to accelerate the scaling of these materials for commercial devices.

In terms of strategic outlook, the next few years are expected to see further breakthroughs in defect reduction, larger crystal sizes, and tailored doping—all critical for expanding the functionality of NLO crystals. The push towards integration with photonic chips and quantum devices is also motivating joint initiatives between manufacturers and research institutions. Companies are increasingly investing in automation and AI-driven quality control to enhance reproducibility and throughput. With growing demand across telecommunications, defense, and medical imaging, industry leaders are poised to deliver innovations that will shape the next generation of photonic technologies.

Growth Drivers: Telecom, Quantum, Medical, and Defense Applications

The fabrication of nonlinear optical (NLO) crystals is experiencing robust growth in 2025, propelled by expanding applications across telecom, quantum technologies, medical devices, and defense systems. These sectors are collectively driving advancements in both the quality and scale of NLO crystal manufacturing.

In telecommunications, the global rollout of advanced optical networks—particularly with the proliferation of 5G and the preparation for future 6G architectures—demands ever-efficient frequency conversion and signal processing. NLO crystals such as lithium niobate (LiNbO3), potassium titanyl phosphate (KTP), and periodically poled materials are critical for wavelength conversion and optical modulation components. Leading suppliers, including Thorlabs and CASTECH, are reporting increased production of custom and large-aperture crystals for telecom photonics, with ongoing investments in defect reduction and scalability.

Quantum technologies represent a rapidly growing demand center. Quantum computing and communications depend on high-purity, low-loss crystals for single-photon generation, entanglement, and up/down-conversion processes. Fabricators are optimizing crystal growth techniques—such as the Czochralski and hydrothermal methods—to boost homogeneity and reduce absorption losses. Companies like Crylink and Newlight Photonics are expanding their offerings to meet specifications for quantum photonic integrated circuits, with a focus on periodically poled LiNbO3 and KTP.

Medical technology is another key growth driver, with NLO crystals fundamental to advanced imaging modalities (e.g., multiphoton microscopy, optical coherence tomography), laser surgery, and diagnostic devices. The need for high-damage-threshold, biocompatible crystals is stimulating innovation in crystal doping and surface finishing. Manufacturers such as Fujikura and CASTECH are developing new crystal compositions and coatings to improve performance in medical laser systems.

The defense sector continues to invest in NLO crystals for directed energy weapons, secure communications, and advanced sensing. There is a particular emphasis on large-size, high-damage-threshold crystals for high-power laser applications. Efforts are underway to enhance crystal uniformity and durability to withstand harsh operational environments, with companies like Northrop Grumman engaged in collaborative research and supply chain development.

Looking ahead, the outlook for NLO crystal fabrication is strong. Demand for higher performance, tailored crystal properties, and scalable production methods is expected to intensify. Industry participants are investing in automation, AI-driven process control, and new material systems, positioning the field for continued growth and innovation through the late 2020s.

Regional Analysis: Asia-Pacific, North America, Europe, and Emerging Markets

The global landscape of nonlinear optical (NLO) crystal fabrication in 2025 is characterized by dynamic activity across Asia-Pacific, North America, Europe, and select emerging markets. The Asia-Pacific region, led by China and Japan, continues to dominate both in production volume and technological innovation. Major Chinese producers such as CASTON and Fujian Castech have expanded their manufacturing capacities, focusing on lithium niobate (LiNbO3), beta-barium borate (BBO), and potassium titanyl phosphate (KTP) crystals to supply global photonics and laser system integrators. Japan remains influential, with companies like Shinkosha advancing crystal growth techniques and quality control, especially for mid-infrared and UV applications.

In North America, the focus is on high-specification, custom nonlinear crystals for defense, aerospace, and quantum optics. The United States, with established players like Northrop Grumman and Gooch & Housego, invests heavily in R&D for next-generation periodically poled materials and hybrid composite crystals targeting quantum communication and high-power laser markets. Canada’s Institute for Ultrafast Spectroscopy and Lasers collaborates regionally on novel crystal engineering, while North American startups are exploring scalable, automated fabrication for rapid prototyping and specialty markets.

European production is centered in Germany, France, and Switzerland, where companies like Crylink and CILAS emphasize ultra-high-purity and precision-cut NLO crystals for medical imaging, ultrafast laser sources, and industrial processing. Germany’s robust photonics cluster supports advances in crystal doping and laser damage threshold enhancement, with EU-funded projects fostering international supply chain resilience and material innovation.

Emerging markets, notably India and South Korea, are rapidly scaling their capabilities, driven by government initiatives to localize advanced photonics manufacturing. Indian organizations such as Bharat Electronics Limited are investing in indigenous crystal growth and processing technologies, aiming to support domestic defense and telecom sectors. South Korean entities are leveraging semiconductor manufacturing expertise to push miniaturization and integration of NLO devices.

Looking ahead, regional competition is expected to intensify, with Asia-Pacific maintaining volume leadership, North America and Europe leading in specialty applications and innovation, and emerging markets closing the technological gap. Strategic partnerships, supply chain localization, and sustainability in crystal growth processes are poised to shape the competitive landscape through 2025 and beyond.

Market Forecast 2025-2030: Revenue, Volume, and Demand Trends

The global market for nonlinear optical (NLO) crystals fabrication is poised for robust growth between 2025 and 2030, underpinned by rising demand in high-performance photonic and laser applications. The surge in adoption of NLO crystals—including lithium niobate (LiNbO3), beta barium borate (BBO), potassium titanyl phosphate (KTP), and periodically poled materials—reflects their critical role in frequency conversion, quantum optics, telecommunication, medical imaging, and industrial laser systems.

Leading manufacturers such as Coherent, EKSMA Optics, CASTON, and Crylink continue to invest in both capacity expansion and process innovation to meet escalating order volumes. In 2025, the market is seeing accelerated deployment of advanced crystal growth techniques—such as Czochralski and top-seeded solution growth (TSSG)—to achieve larger, high-purity boules with improved damage thresholds, catering to next-generation ultrafast and high-power laser systems. Demand from sectors such as semiconductor lithography, quantum communication, and medical diagnostics is driving volume orders, especially for custom-cut and periodically poled crystals.

Volume shipments of NLO crystals are expected to increase steadily through 2025–2027, with the Asia-Pacific region—led by China, Japan, and South Korea—remaining the fastest-growing manufacturing and end-user base. Expansion by regional players, such as CASTON and Crylink, is contributing to heightened global supply chain resilience and shorter lead times. The European and North American markets are also forecast to post healthy growth, driven by government-backed quantum technology initiatives and investments in photonics infrastructure.

Revenue projections for the sector indicate a mid- to high-single-digit compound annual growth rate (CAGR) from 2025 to 2030. The push toward scalable fabrication of high-quality, low-defect crystals is expected to sustain premium pricing, especially for specialty materials and large-aperture components. Key trends influencing demand include miniaturization of photonic devices, rapid adoption of ultraviolet and deep-ultraviolet (DUV) laser sources, and integration of NLO crystals in emerging quantum computing and encryption systems.

In the near term, manufacturers are focused on automation, yield improvement, and supply chain localization. The outlook for 2025–2030 is optimistic, with the sector positioned to benefit from the convergence of quantum-era technologies and the continuing proliferation of advanced laser platforms worldwide.

Supply Chain and Quality Control: Challenges and Solutions

The fabrication of nonlinear optical (NLO) crystals in 2025 stands at the intersection of advanced material science and demanding supply chain logistics. As these crystals—such as lithium niobate (LiNbO₃), beta barium borate (BBO), potassium titanyl phosphate (KTP), and periodically poled variants—find increasing roles in quantum optics, telecommunications, and laser systems, maintaining reliable supply and high-quality standards remains both a challenge and a driving force for innovation.

One of the primary supply chain challenges is the sourcing of ultrapure raw materials. The optical performance of NLO crystals is strongly dependent on material purity and defect control. Leading manufacturers such as CASTECH Inc. and Crylink emphasize vertically integrated production systems to control every stage from raw material selection to crystal growth and post-processing. This integration is crucial for mitigating risks related to the scarcity or fluctuation of high-quality feedstock, which can be affected by geopolitical and environmental factors.

Another persistent issue is the precision required in crystal growth. Techniques such as the Czochralski and flux methods demand strict temperature and environmental controls to minimize defects, inclusions, and striations. Even minor inconsistencies can dramatically reduce nonlinear conversion efficiencies. As a result, companies like Fujicrystal and Ekspress-Laser are investing in automation and real-time monitoring systems to enhance reproducibility and scalability while reducing yield losses.

Quality control is increasingly leveraging advanced metrology, including high-resolution X-ray diffraction and laser-based inspection. Such methods allow for early detection of structural imperfections and impurities, facilitating corrective actions before costly downstream processing. Moreover, there is a growing focus on the traceability of production batches and full documentation, which is particularly important for customers in defense, aerospace, and quantum technology sectors.

Looking ahead, the outlook for the NLO crystal supply chain is shaped by two main trends: regional diversification and sustainability. Major producers in China, Europe, and Japan are expanding their domestic capacities to reduce reliance on single-source suppliers, responding to recent disruptions in global logistics. Simultaneously, there is increasing attention to environmental best practices, with manufacturers adopting greener solvents and recycling protocols for crystal growth byproducts.

In summary, the fabrication and supply of NLO crystals in 2025 is characterized by heightened quality control, strategic supply chain management, and a shift toward more sustainable and resilient operations. These developments are expected to support the growing global demand for high-performance nonlinear optical components across diverse photonics applications.

Sustainability and Green Manufacturing Initiatives

Sustainability and green manufacturing have become central to the evolution of nonlinear optical (NLO) crystal fabrication as the sector responds to increasing environmental regulations and market demand for eco-friendly photonic components. In 2025, leading producers are emphasizing the reduction of toxic byproducts, energy-efficient growth processes, and the responsible sourcing of raw materials.

A significant shift observed is the move away from traditional crystal growth methods—such as the Czochralski and Bridgman techniques—that often require high energy input and generate considerable waste, particularly with materials like lithium niobate and potassium titanyl phosphate. Manufacturers are now prioritizing innovations such as low-temperature hydrothermal synthesis and advanced flux growth, processes that operate under milder conditions and minimize emissions. For instance, CASTECH Inc., one of the world’s largest suppliers of NLO crystals, has reported ongoing upgrades to their hydrothermal growth facilities, aiming to cut energy consumption per kilogram of output while recycling process water and reagents.

Another prominent approach is the adoption of closed-loop and circular manufacturing systems. Companies such as CRYTUR are investing in recycling scrap and off-spec crystal material directly back into the production chain, both to reduce raw material demand and to avoid landfill disposal. These efforts are complemented by increased traceability of feedstock, with manufacturers working to ensure their lithium, tantalum, and rare earth supplies are sourced according to internationally recognized environmental and ethical standards.

The industry’s response to sustainability is also driven by the end-user markets—telecommunications, quantum computing, and medical imaging—which increasingly require transparent supply chains and certified low-impact products. This is prompting NLO crystal suppliers to pursue third-party certifications and participate in industry-wide sustainability initiatives. For example, SHINKOSHA has publicized its alignment with the Responsible Minerals Initiative and is developing formal Environmental Product Declarations (EPDs) for its crystal components.

Looking ahead to the next few years, the outlook is for even greater integration of green chemistry principles. There is growing R&D investment in solvent-free synthesis routes and the substitution of hazardous chemicals with benign alternatives. Industry consortia and standards bodies are expected to roll out new guidelines for energy use, waste handling, and lifecycle analysis specific to NLO crystal fabrication, further driving progress toward sustainability benchmarks.

Future Outlook: Next-Gen Materials and Strategic Roadmaps

The landscape of nonlinear optical (NLO) crystal fabrication is poised for dynamic evolution in 2025 and the near future, driven by escalating demands from quantum photonics, high-power laser systems, and integrated photonic circuits. Leading industry participants and research consortia are prioritizing the development of next-generation materials that offer broader transparency ranges, higher damage thresholds, and tailored phase-matching capabilities critical for advanced photonic applications.

Major manufacturers such as CASTECH and CRYLINK continue to invest in the scaling and refinement of classical NLO crystals like BBO (beta barium borate), LBO (lithium triborate), and KTP (potassium titanyl phosphate). However, attention is rapidly shifting to novel materials, such as periodically poled crystals and wide-bandgap semiconductors. These emerging materials promise enhanced performance in wavelength conversion, frequency mixing, and ultrafast pulse generation, extending operational possibilities for next-generation laser and quantum systems.

The fabrication of periodically poled lithium niobate (PPLN) and related quasi-phase-matched materials is entering a new phase, with improved domain engineering and wafer-scale production capabilities. Companies are deploying advanced poling techniques and precision lithographic patterning to enable high-yield, large-area crystals suitable for integration into photonic chips. For example, Shinkosha and CASTECH are expanding their offerings to support the growing demand for PPLN and PPKTP crystals tailored for telecom, quantum key distribution, and frequency comb generation.

In parallel, materials such as gallium arsenide (GaAs) and gallium phosphide (GaP) are gaining traction for their high nonlinear coefficients and compatibility with semiconductor fabrication processes. The integration of NLO crystals with silicon photonics platforms is a primary target, enabling compact, high-efficiency frequency converters for data communications and emerging quantum technologies. Collaborative efforts between crystal manufacturers and photonic foundries, such as those led by SICCAS, are expected to accelerate hybrid integration and open new markets in the mid-infrared and terahertz spectral domains.

Strategically, the sector is embracing automation, in-line quality monitoring, and AI-driven process control to boost yield and reduce defect rates. Sustainability and supply chain resilience are also in focus, with companies evaluating recycling processes and alternative feedstocks for crystal growth. Over the next few years, the convergence of material innovation, precision fabrication, and integration with photonic platforms will define the roadmap for nonlinear optical crystals, positioning the sector at the heart of the photonics revolution.