Quantum Hall Effect Sensors: The Next Leap in Ultra-Precise Magnetic Field Detection. Discover How This Quantum Phenomenon Is Shaping the Future of Sensing Technology.

- Breaking News: Recent Advances in Quantum Hall Effect Sensor Technology

- Understanding the Quantum Hall Effect: Fundamentals and Significance

- How Quantum Hall Effect Sensors Work: Principles and Mechanisms

- Key Applications: From Metrology to Next-Gen Electronics

- Comparing Quantum Hall Sensors to Traditional Magnetic Sensors

- Challenges and Limitations in Current Sensor Designs

- Industry Impact: Market Growth and Leading Innovators

- Future Prospects: Emerging Trends and Research Directions

- Sources & References

Breaking News: Recent Advances in Quantum Hall Effect Sensor Technology

Recent years have witnessed remarkable progress in the development and application of Quantum Hall Effect (QHE) sensor technology, driven by advances in material science, device engineering, and quantum metrology. Notably, the integration of two-dimensional materials such as graphene has enabled the fabrication of QHE sensors that operate at higher temperatures and lower magnetic fields than traditional gallium arsenide-based devices. This breakthrough significantly broadens the practical utility of QHE sensors, making them more accessible for industrial and laboratory applications National Institute of Standards and Technology.

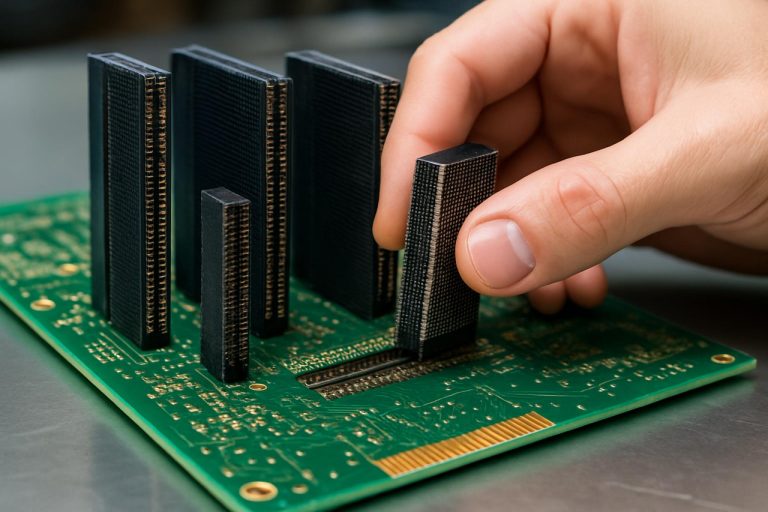

Another major advance is the miniaturization and on-chip integration of QHE sensors, which has paved the way for their use in compact, portable measurement systems. These innovations are particularly relevant for precision magnetic field sensing, electrical resistance standards, and quantum resistance metrology. For instance, recent prototypes have demonstrated robust quantization of Hall resistance at temperatures as high as 10 K, reducing the need for expensive cryogenic infrastructure Physikalisch-Technische Bundesanstalt.

Furthermore, the development of scalable fabrication techniques, such as chemical vapor deposition for large-area graphene, is accelerating the commercialization of QHE sensors. These advances are expected to impact fields ranging from fundamental physics research to the calibration of electrical instruments and the development of next-generation quantum technologies National Physical Laboratory.

Understanding the Quantum Hall Effect: Fundamentals and Significance

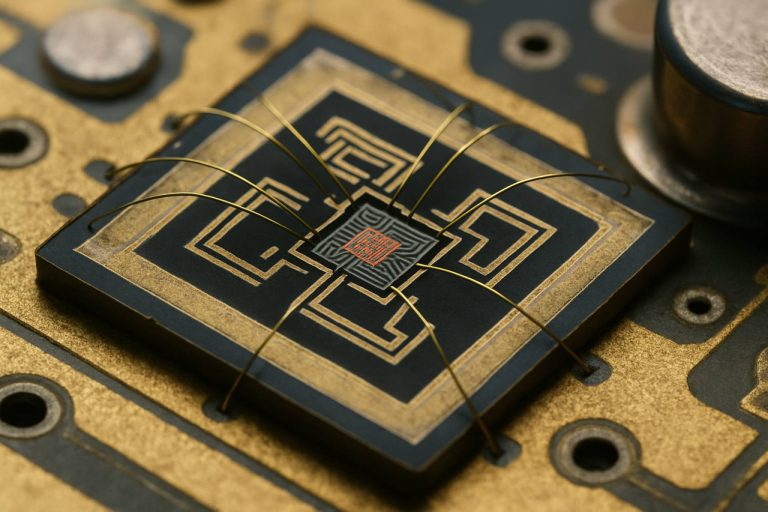

The Quantum Hall Effect (QHE) is a quantum phenomenon observed in two-dimensional electron systems subjected to low temperatures and strong perpendicular magnetic fields. Under these conditions, the Hall resistance becomes quantized, taking on discrete values that are integer or fractional multiples of fundamental constants. This quantization is remarkably precise and robust against impurities or material defects, making the QHE a cornerstone in the field of condensed matter physics. The effect was first discovered in 1980 by Klaus von Klitzing, who demonstrated that the Hall resistance in a silicon MOSFET device exhibited plateaus at values defined by the ratio of Planck’s constant to the square of the electron charge (The Nobel Prize).

The significance of the QHE extends beyond fundamental physics. Its extraordinary precision has led to the redefinition of the standard for electrical resistance, with the von Klitzing constant now serving as a universal reference (Bureau International des Poids et Mesures). In the context of sensor technology, the QHE provides a unique platform for developing highly sensitive and stable magnetic field sensors. Quantum Hall Effect sensors exploit the quantized Hall resistance to achieve unparalleled accuracy in magnetic field measurements, with applications ranging from metrology and fundamental research to industrial and medical instrumentation (National Institute of Standards and Technology). The robustness of the QHE against environmental perturbations ensures that these sensors maintain their performance even under challenging conditions, underscoring the profound impact of quantum phenomena on practical device engineering.

How Quantum Hall Effect Sensors Work: Principles and Mechanisms

Quantum Hall Effect (QHE) sensors operate based on the quantum mechanical phenomenon observed in two-dimensional electron systems subjected to low temperatures and strong perpendicular magnetic fields. When a current flows through such a system, the application of a magnetic field causes the electrons to move in quantized circular orbits, leading to the formation of discrete energy levels known as Landau levels. As the magnetic field strength increases, the Hall resistance exhibits plateaus at precise values, which are integer multiples of fundamental constants. This quantization is remarkably robust against impurities and material defects, making QHE sensors highly reliable and reproducible for precision measurements.

The core mechanism involves measuring the Hall voltage, which develops perpendicular to both the current and the magnetic field. In the quantum regime, this voltage is directly proportional to the applied magnetic field and inversely proportional to the electron density, but with quantized steps. The quantized Hall resistance is given by ( R_H = frac{h}{ie^2} ), where ( h ) is Planck’s constant, ( e ) is the elementary charge, and ( i ) is an integer (the filling factor). This relationship enables QHE sensors to serve as primary standards for resistance and magnetic field measurements, with unparalleled accuracy and stability.

Modern QHE sensors are typically fabricated using high-mobility semiconductor heterostructures, such as GaAs/AlGaAs, or more recently, graphene, which allows for operation at higher temperatures and lower magnetic fields. The exceptional precision and robustness of QHE sensors have led to their adoption in metrology laboratories worldwide, underpinning the redefinition of the SI unit of resistance (International Bureau of Weights and Measures (BIPM)).

Key Applications: From Metrology to Next-Gen Electronics

Quantum Hall Effect (QHE) sensors have emerged as pivotal components in a range of advanced technological applications, owing to their exceptional precision and stability. In metrology, QHE sensors are foundational for the realization and maintenance of the resistance standard. The quantized Hall resistance, which is defined by fundamental constants, enables national metrology institutes to calibrate resistance with unparalleled accuracy, supporting the global uniformity of electrical measurements (National Institute of Standards and Technology). This has direct implications for industries reliant on precise electrical standards, such as semiconductor manufacturing and telecommunications.

Beyond metrology, QHE sensors are increasingly being integrated into next-generation electronic devices. Their high sensitivity to magnetic fields and robustness against environmental noise make them ideal for applications in magnetic field sensing, including in medical imaging technologies like magnetoencephalography and in navigation systems for aerospace and automotive industries (Physikalisch-Technische Bundesanstalt). Furthermore, the miniaturization and integration of QHE sensors with semiconductor platforms are paving the way for their use in quantum computing and spintronics, where precise control and measurement of quantum states are essential (IBM Quantum).

As research advances, the unique properties of QHE sensors—such as their immunity to drift and high linearity—are expected to drive innovation in both fundamental science and commercial electronics, solidifying their role as a cornerstone technology in the era of quantum-enabled devices.

Comparing Quantum Hall Sensors to Traditional Magnetic Sensors

Quantum Hall Effect (QHE) sensors offer several distinct advantages over traditional magnetic sensors such as Hall effect sensors, magnetoresistive sensors, and fluxgate magnetometers. The primary distinction lies in the quantum mechanical nature of the QHE, which enables extremely high precision and stability in magnetic field measurements. Unlike conventional Hall sensors, which are limited by material imperfections and temperature fluctuations, QHE sensors operate at quantized resistance plateaus, resulting in exceptional reproducibility and immunity to environmental variations. This makes them particularly suitable for applications requiring metrological accuracy, such as the realization of resistance standards and calibration of magnetic fields (National Institute of Standards and Technology).

Traditional magnetic sensors, while more accessible and cost-effective, often suffer from drift, nonlinearity, and limited sensitivity, especially at very low or very high magnetic fields. Magnetoresistive sensors, for example, are sensitive to temperature and can exhibit hysteresis, while fluxgate magnetometers are bulky and require complex feedback electronics. In contrast, QHE sensors, when operated at low temperatures and high magnetic fields, provide a direct link to fundamental physical constants, ensuring unparalleled accuracy (Physikalisch-Technische Bundesanstalt).

However, the practical deployment of QHE sensors is currently constrained by the need for cryogenic temperatures and strong magnetic fields, which limits their use outside specialized laboratories. Ongoing research aims to develop QHE-based devices that function at higher temperatures and lower fields, potentially bridging the gap between quantum and traditional sensor technologies (Nature Publishing Group).

Challenges and Limitations in Current Sensor Designs

Quantum Hall Effect (QHE) sensors offer exceptional precision in magnetic field measurements, but their practical deployment faces several challenges and limitations. One primary issue is the requirement for extremely low operating temperatures, often below 4 K, to achieve the quantized Hall resistance necessary for high-accuracy sensing. This necessitates the use of complex and costly cryogenic systems, limiting the sensors’ applicability in everyday environments and increasing operational costs National Institute of Standards and Technology.

Material quality is another significant constraint. QHE sensors rely on high-mobility two-dimensional electron gas (2DEG) systems, typically fabricated from materials such as GaAs/AlGaAs heterostructures. The fabrication process demands ultra-clean environments and advanced epitaxial growth techniques, which can be expensive and difficult to scale for mass production American Physical Society. Additionally, device miniaturization is limited by the need to maintain high electron mobility and low disorder, which becomes increasingly challenging as device dimensions shrink.

Another limitation is the sensitivity to external perturbations, such as electromagnetic interference and mechanical vibrations, which can degrade measurement accuracy. Furthermore, the integration of QHE sensors with conventional electronics remains complex due to the need for specialized readout circuitry and the incompatibility of cryogenic operation with standard semiconductor processes IEEE.

Addressing these challenges requires advances in material science, cryogenics, and device engineering to enable broader adoption of QHE sensors in practical applications.

Industry Impact: Market Growth and Leading Innovators

Quantum Hall Effect (QHE) sensors are emerging as transformative components in precision measurement and sensing applications, driving significant market growth across various industries. The unique ability of QHE sensors to provide highly accurate, stable, and reproducible measurements of magnetic fields and electrical resistance has positioned them at the forefront of next-generation sensor technologies. The global market for QHE sensors is projected to expand rapidly, fueled by increasing demand in sectors such as automotive, aerospace, medical diagnostics, and quantum computing. This growth is underpinned by the sensors’ robustness in extreme environments and their potential for miniaturization, which is critical for integration into advanced electronic systems.

Leading innovators in the QHE sensor market include established semiconductor companies and specialized research-driven enterprises. For instance, National Institute of Standards and Technology (NIST) has played a pivotal role in advancing QHE sensor technology, particularly in the development of quantum resistance standards. Companies like Infineon Technologies AG and Allegro MicroSystems are actively integrating QHE-based solutions into their product portfolios, targeting automotive and industrial automation markets. Additionally, startups and research institutions are contributing to the innovation landscape by exploring novel materials, such as graphene, to enhance sensor sensitivity and reduce production costs.

The competitive landscape is characterized by strategic collaborations between academia and industry, fostering rapid prototyping and commercialization of QHE sensor technologies. As the market matures, continued investment in research and development is expected to yield further breakthroughs, solidifying the role of QHE sensors in the future of precision sensing and measurement.

Future Prospects: Emerging Trends and Research Directions

The future of Quantum Hall Effect (QHE) sensors is shaped by rapid advancements in material science, device miniaturization, and integration with quantum technologies. One emerging trend is the exploration of two-dimensional (2D) materials, such as graphene and transition metal dichalcogenides, which exhibit robust quantum Hall states even at relatively high temperatures. These materials promise to extend the operational range and sensitivity of QHE sensors, making them more practical for real-world applications beyond laboratory environments. Research is also focusing on the development of scalable fabrication techniques, enabling the mass production of QHE sensors with consistent performance characteristics Nature Nanotechnology.

Another significant direction is the integration of QHE sensors with quantum computing and communication systems. Their inherent precision and stability make them ideal candidates for quantum metrology, where they can serve as standards for resistance and magnetic field measurements. Additionally, the miniaturization of QHE devices is opening new possibilities for their use in portable and wearable technologies, particularly in biomedical diagnostics and environmental monitoring National Institute of Standards and Technology (NIST).

Looking ahead, interdisciplinary collaborations between physicists, engineers, and materials scientists are expected to accelerate the translation of QHE sensor research into commercial products. The ongoing refinement of device architectures, combined with advances in cryogenics and low-noise electronics, will likely further enhance the performance and accessibility of QHE sensors, solidifying their role in next-generation sensing technologies IEEE.

Sources & References

- National Institute of Standards and Technology

- Physikalisch-Technische Bundesanstalt

- National Physical Laboratory

- The Nobel Prize

- Bureau International des Poids et Mesures

- IBM Quantum

- Nature Publishing Group

- IEEE

- Infineon Technologies AG

- Allegro MicroSystems