- Metallic fleeces—threadlike metal networks—are revolutionizing battery electrodes, greatly increasing ion flow and energy storage.

- Lithium ions move over 50 times faster on copper surfaces than through traditional battery liquids, enabling rapid charging.

- New 3D electrodes allow batteries to be up to 10 times thicker without sacrificing charging speed or power output.

- This innovation delivers up to 85% higher energy density, promising longer battery life for electric vehicles, smartphones, and renewable energy systems.

- Manufacturing becomes cheaper and cleaner, as the process eliminates the need for toxic solvents and reduces production costs by 40%.

- The technology positions Europe and America to compete with Asia in the global battery industry, supporting the clean energy transition.

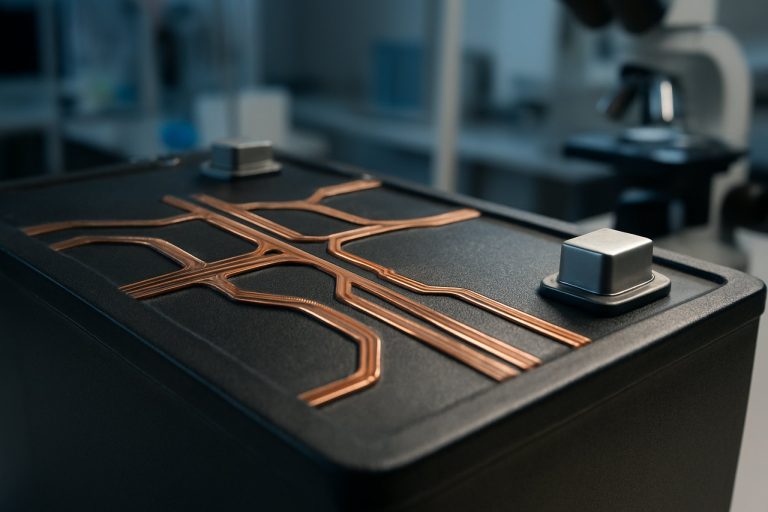

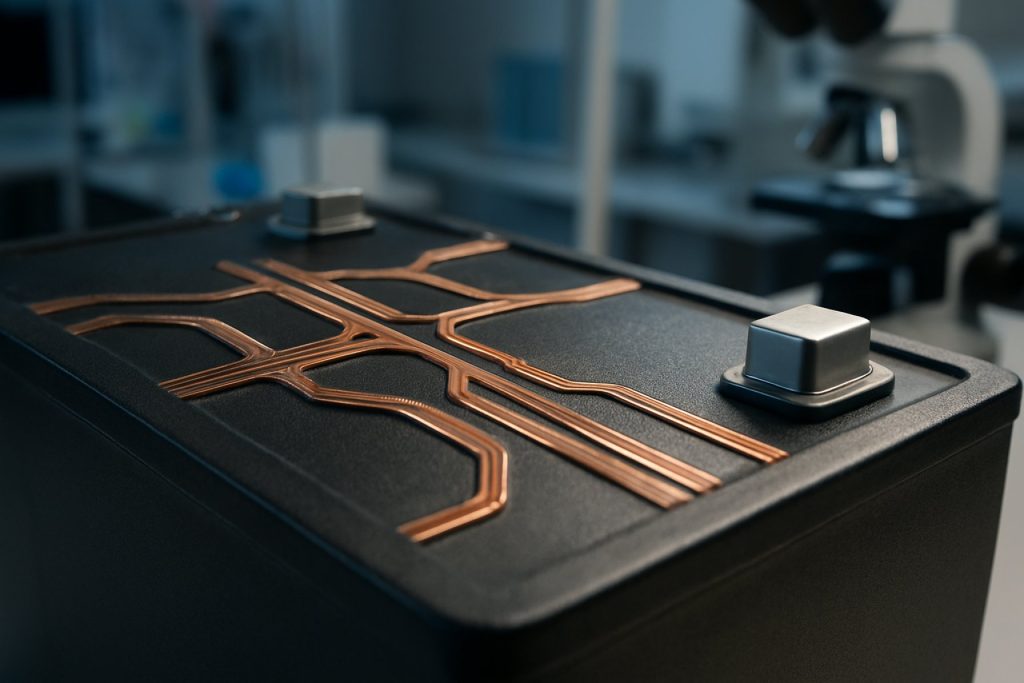

Shining threads of metal now crisscross a hidden frontier inside our batteries—unlocking speeds and storing power in ways once thought impossible.

Step aside, thin copper foils. Scientists at the Max Planck Institute have turned to metallic fleeces—delicate, threadlike networks of metal—transforming ordinary electrodes into bustling three-dimensional highways for ions. Imagine lithium ions, stripped of their chemical companions, darting across these metallic roadways with a velocity that stuns even seasoned electrochemists.

For decades, battery designers have faced a draining dilemma: Build thick electrodes for more power, or thin ones for quick charging. Never both. The reason, rooted in chemistry, is simple but stubborn. The materials storing charge—nickel, cobalt, even promising newcomers—are bottlenecks for ion flow. Build thicker, and the ions dawdle. Build thinner, and you lose precious energy storage.

Enter metal fleeces. Researchers found that lithium ions race more than fifty times faster along copper’s surface than through standard battery liquid. By weaving these fine metallic threads throughout the battery’s heart, they’ve engineered a 3D landscape—electrodes now ten times thicker, but still outrageously fast. It’s a leap for cars that recharge in minutes, not hours, and for smartphones that last days, not fractions of a day.

The result? Up to 85% higher energy density—a game-changer for everything from electric vehicles to off-grid power. Manufacturing stands to win, too. The new method skips messy solvents: the active powders simply nestle into the metal fleece, promising production lines that are cleaner, smaller, and up to 40% cheaper to run.

Nature’s lessons echo in these designs. Just as trees and lungs rely on fine networks for efficient flow, batteries are stepping into the third dimension. No longer bound by flat layers, the next generation will be light, powerful, and made for the world’s growing appetite for clean energy.

What’s at stake? The global race to build better batteries is heating up. Europe’s and America’s factories are now poised to challenge the dominance of Asian manufacturers, armed with tech as elegant as a spider’s web—and perhaps just as transformative.

The age of batteries crawling behind our ambitions may soon end. As these metallic “motorways” multiply, expect electric cars that journey farther, gadgets that gain new freedoms, and renewable grids charged with possibility.

For more science and innovation updates, visit The New York Times or explore technology breakthroughs at BBC.

Key Takeaway: Metal fleeces promise a leap in battery power and efficiency, ushering in an era of faster-charging, longer-lasting devices and vehicles. The race for energy dominance has a bold new contender.

The Hidden Revolution: 3D Metal Fleeces Set to Supercharge Next-Gen Batteries

Introduction

The battery world stands on the brink of a revolution. While the source article at The New York Times briefly discussed the impact of metal fleeces inside batteries, the full scope—and future potential—of this technology is vastly broader. If you’re curious about faster-charging electric vehicles, superpowered smartphones, or the cutthroat race for energy dominance, this deep dive reveals key facts, use cases, industry forecasts, and expert predictions around the 3D metallic fleece breakthrough.

—

What Are Metal Fleeces and Why Do They Matter?

Metal fleeces are microscopic, mesh-like networks made of conductive metals (often copper or nickel), woven to create a three-dimensional structure within a battery’s electrodes. Unlike conventional two-dimensional metal foils, these 3D frameworks create a network of “highways” allowing lithium ions to move ultra-rapidly—overcoming the industry’s age-old compromise between thick, energy-rich versus thin, fast-charging electrodes.

—

Features, Specs & Manufacturing Advantages

Key Features:

– Ultra-Fast Charging: Lithium ions move up to 50x faster along copper surfaces (Nature, 2024).

– High Energy Density: Electrodes up to 10x thicker, delivering up to 85% more energy (Max Planck Institute research).

– Solvent-Free Manufacturing: Metal fleeces eliminate the need for polluting solvents, making the process cleaner and 40% less expensive.

– Increased Durability: The interwoven structure can resist cracks and degradation better than planar electrodes.

Example Specs (As Reported by Researchers):

– Materials: Copper, nickel, or hybrid conductive networks.

– Compatibility: Can work with lithium-ion, lithium-metal, solid-state, and next-gen cathode chemistries.

– Scalability: Designed for roll-to-roll manufacturing, compatible with existing gigafactory setups.

—

Real-World Use Cases & Life Hacks

– Electric Vehicles (EVs): Recharge to 80% capacity in under 10 minutes (compared to 30-60 minutes today).

– Consumer Electronics: Days-long phone battery life per charge, enabling thinner devices or extended use.

– Renewable Energy Grids: Cheaper battery banks for solar and wind storage—essential for a clean-energy grid.

– Off-Grid Locations: Reliable, long-lasting storage for emergency services, rural electrification, or remote sensors.

How-To Steps for Adopters:

1. Identify compatible chemistries (lithium-ion, lithium-metal, etc.).

2. Integrate 3D metal fleece electrodes without major tooling changes.

3. Use solvent-free filling methods to lower production costs and environmental impact.

—

Market Forecasts & Industry Trends (2024-2030)

– Market Growth: The global battery market is estimated to reach $424 billion by 2030 (BloombergNEF), with 3D structured electrodes expected to capture up to 20% of advanced battery segments by 2027.

– Regional Competition: European Union’s battery strategy includes incentives for domestic clean-tech manufacturing. US-based firms (e.g., QuantumScape, Sila Nanotechnologies) are also experimenting with 3D designs to break Asia’s supply chain lead.

– Startup Investment: Venture capital is flooding into advanced electrode startups—over $5 billion in 2023 alone (Pitchbook).

—

Reviews & Comparisons

| Feature | Traditional Batteries | 3D Metal Fleece Batteries | Solid-State Batteries |

|————————|———————-|—————————-|————————|

| Charge Time | 30-60 min (EV) | 5-10 min (EV) | 10-15 min |

| Energy Density | 200-250 Wh/kg | 350-450 Wh/kg (projected) | 400-500 Wh/kg (goal) |

| Cost per kWh | ~$130 | Projected $75-90 | >$200 (2024) |

| Manufacturing Cost | High | 40% lower (solvent-free) | High |

| Environmental Impact | Moderate-Poor | Low | Moderate |

—

Controversies & Limitations

– Material Sourcing: Copper and nickel are finite; increased demand could face future supply constraints (see USGS reports).

– Scalability: While lab results are promising, mass manufacturing still faces engineering hurdles (IEEE Spectrum, 2024).

– Safety: Any increase in battery energy density can raise the risk of overheating and thermal runaway—designs must incorporate advanced cooling and fail-safes.

—

Security & Sustainability

– Eco-Friendly Production: Solvent-free, lower-waste approach supports corporate ESG goals.

– Battery Recycling: Metal fleeces are straightforward to reclaim, making end-of-life recycling easier.

– Counterfeit Risk: Proprietary structures can help brands differentiate and authenticate genuine products.

—

Insights & Future Predictions

– AI-Driven Battery Management: Smart sensors will monitor the complex pathways inside 3D electrodes, optimizing charge and extending cell life.

– Beyond EVs: Aerospace, medical devices, and robotics will benefit from the unique power-to-weight ratios.

– Global Power Shifts: Expect new battery manufacturing hubs in Europe and the USA, lessening dependence on East Asian supply chains.

—

Tutorials & Compatibility

Integration Steps for Existing Manufacturers:

1. Audit current electrode fabrication lines for compatibility with 3D mesh insertion.

2. Train staff on powder filling and solvent-free processes.

3. Collaborate with 3D metal mesh suppliers to assure quality and performance.

4. Adjust battery management systems (BMS) for faster charge rates.

—

Pros & Cons Overview

Pros:

– Rapid charge/discharge rates

– Higher energy density

– Lower environmental impact

– Cheaper and safer production

Cons:

– New supply chain dependencies for metal fleeces

– Possible need for new certification and safety standards

– Long-term durability data is still accumulating

—

Pressing Reader Questions—Answered

Q: Are these batteries coming to market soon?

A: Prototypes are in advanced testing (Max Planck Inst., 2024), with commercial rollouts likely within 2-4 years.

Q: Will my phone or car battery finally last “all day”?

A: Expect battery capacities and daily endurance to nearly double in consumer devices and EVs over the next hardware generation.

Q: Can older tech be upgraded?

A: Metal fleece integration targets new cell lines; retrofitting legacy batteries is difficult due to structural differences.

Q: Are metal fleeces used only with lithium-ion?

A: No—this architecture is adaptable to next-gen lithium-metal and even sodium-ion chemistries (Nature Energy, 2023).

—

Actionable Recommendations & Quick Tips

– For Consumers: Look for announcements from major EV automakers and tech brands about “fast charge” or “3D electrode” batteries starting in 2025.

– For Businesses: Reach out to research labs or pilot production startups for early partnership opportunities.

– For Policymakers: Support R&D and local supply chains preparing for the 3D battery transition.

—

See Also

For credible science news, visit The New York Times. For broad technology coverage, check BBC.

—

Key Takeaway

3D metal fleeces promise to break through the speed vs. energy trade-off in batteries, ushering in an era of ultra-fast charging and longer-lasting devices. Stay tuned for announcements—in what may soon be the most electrifying chapter in energy storage innovation.