2025 Xenon-Based Excimer Laser Manufacturing Industry Report: Market Dynamics, Growth Projections, and Strategic Insights for the Next 5 Years

- Executive Summary & Market Overview

- Key Technology Trends in Xenon-Based Excimer Lasers

- Competitive Landscape and Leading Manufacturers

- Market Growth Forecasts (2025–2030): CAGR, Revenue, and Volume Analysis

- Regional Market Analysis: North America, Europe, Asia-Pacific, and Rest of World

- Challenges and Opportunities in Xenon-Based Excimer Laser Manufacturing

- Future Outlook: Innovation, Investment, and Emerging Applications

- Sources & References

Executive Summary & Market Overview

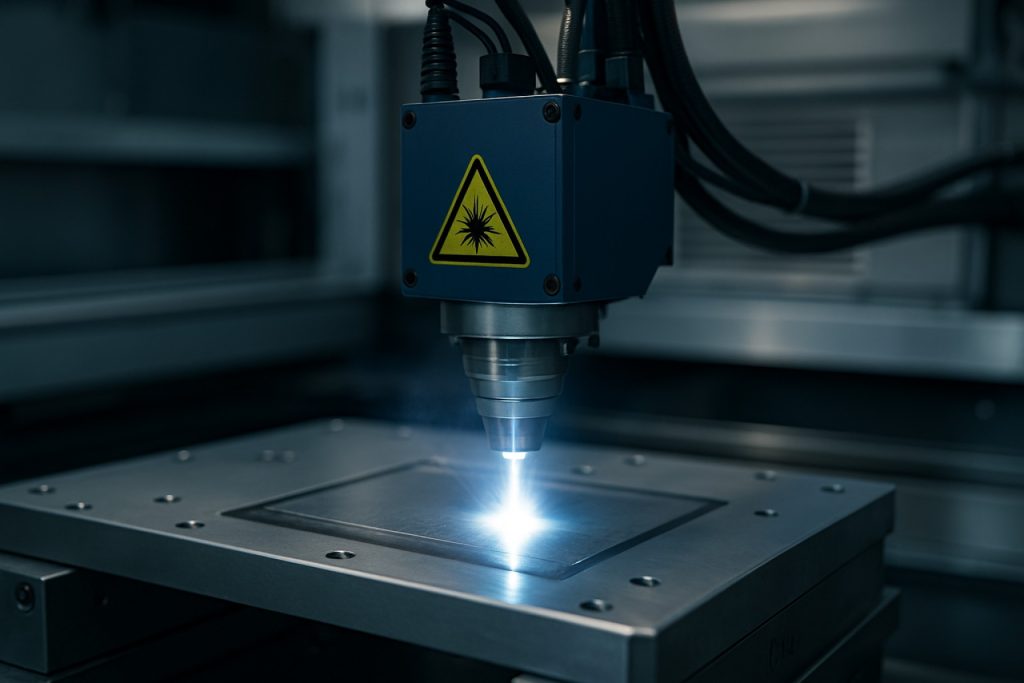

The xenon-based excimer laser manufacturing market is poised for significant growth in 2025, driven by expanding applications in semiconductor lithography, ophthalmology, and advanced materials processing. Xenon excimer lasers, which generate ultraviolet light through the excitation of xenon and halogen gases, are valued for their high precision, short pulse durations, and ability to process materials with minimal thermal damage. These characteristics make them indispensable in the production of integrated circuits, eye surgeries such as LASIK, and microfabrication of polymers and ceramics.

According to MarketsandMarkets, the global excimer laser market is projected to reach USD 4.1 billion by 2025, with xenon-based systems accounting for a substantial share due to their dominance in photolithography and medical device manufacturing. The semiconductor industry, in particular, is a primary driver, as the ongoing demand for smaller, more powerful chips necessitates advanced lithography techniques that rely on xenon excimer lasers for sub-200 nm patterning.

Regionally, Asia-Pacific leads the market, propelled by the presence of major semiconductor foundries and electronics manufacturers in countries such as Taiwan, South Korea, and China. North America and Europe also maintain strong positions, supported by robust R&D activities and established medical device sectors. Key industry players, including Cymer (a subsidiary of ASML), Coherent Corp., and Nikon Corporation, continue to invest in technological advancements to enhance laser efficiency, reliability, and cost-effectiveness.

- Semiconductor lithography remains the largest application segment, with ongoing investments in EUV and DUV technologies.

- Medical applications, particularly in refractive eye surgery, are expected to see steady growth as demand for minimally invasive procedures rises.

- Materials processing, including micromachining and surface modification, is an emerging area benefiting from the unique properties of xenon excimer lasers.

Challenges persist, including high capital costs, complex maintenance requirements, and the need for skilled operators. However, the market outlook for 2025 remains robust, underpinned by technological innovation and the critical role of xenon-based excimer lasers in next-generation manufacturing and healthcare solutions.

Key Technology Trends in Xenon-Based Excimer Lasers

Xenon-based excimer laser manufacturing is undergoing significant technological evolution as the demand for high-precision photolithography, medical procedures, and advanced materials processing intensifies. In 2025, several key technology trends are shaping the manufacturing landscape for these lasers, driven by the need for greater efficiency, reliability, and miniaturization.

- Advanced Gas Handling and Purification: Manufacturers are investing in sophisticated gas handling systems to ensure the purity and stability of xenon and halogen mixtures. Enhanced purification technologies reduce contamination, extend laser lifespan, and improve pulse-to-pulse energy consistency, which is critical for semiconductor and medical applications. Companies like Linde are developing ultra-high-purity xenon supply chains to support these requirements.

- Precision Optical Component Fabrication: The production of high-durability optical components, such as mirrors and windows, is advancing through the use of novel coatings and substrate materials. These improvements help withstand the high-energy ultraviolet output of xenon-based excimer lasers, reducing maintenance intervals and operational costs. ZEISS and Coherent Corp. are at the forefront of these innovations.

- Modular and Scalable Laser Architectures: To address diverse application needs, manufacturers are adopting modular designs that allow for easy scaling of output power and integration into complex systems. This trend supports rapid customization for end-users in industries such as microelectronics and ophthalmology.

- Automated Quality Control and Diagnostics: The integration of real-time monitoring and AI-driven diagnostics into manufacturing lines is enhancing yield and reducing downtime. Automated systems can detect deviations in gas composition, optical alignment, and pulse characteristics, enabling predictive maintenance and higher throughput. Lam Research and ASML are leveraging these technologies to optimize production.

- Environmental and Energy Efficiency Initiatives: With sustainability becoming a priority, manufacturers are focusing on reducing the environmental footprint of xenon-based excimer laser production. This includes recycling rare gases, minimizing hazardous byproducts, and improving energy efficiency throughout the manufacturing process, as highlighted in recent sustainability reports from USHIO Inc..

These trends collectively reflect a shift toward smarter, cleaner, and more adaptable manufacturing processes, positioning xenon-based excimer lasers for continued growth in high-tech sectors through 2025 and beyond.

Competitive Landscape and Leading Manufacturers

The competitive landscape of the xenon-based excimer laser manufacturing market in 2025 is characterized by a concentrated group of global players, technological innovation, and strategic partnerships. The market is primarily driven by demand from semiconductor lithography, ophthalmology, and advanced materials processing. Key manufacturers are leveraging proprietary technologies, robust R&D pipelines, and global distribution networks to maintain their competitive edge.

Leading the market are established companies such as Coherent Corp., Cymer (an ASML company), and Jenoptik AG. These firms have consistently invested in the development of high-performance xenon-based excimer lasers, focusing on wavelength stability, pulse energy, and system reliability. Cymer, in particular, dominates the semiconductor lithography segment, supplying advanced light sources for deep ultraviolet (DUV) photolithography systems used in leading-edge chip manufacturing. Coherent Corp. and Jenoptik AG have diversified portfolios, serving both industrial and medical markets.

Emerging players, especially from Asia-Pacific, are intensifying competition. Companies such as Gigaphoton Inc. and Nikon Corporation are expanding their excimer laser offerings, targeting both domestic and international markets. These firms are capitalizing on regional demand growth, particularly in China and South Korea, where semiconductor and display manufacturing are rapidly scaling.

Strategic collaborations and supply agreements are shaping the competitive dynamics. For instance, ASML Holding maintains exclusive supplier relationships with Cymer and Gigaphoton Inc. for lithography light sources, reinforcing barriers to entry for new competitors. Additionally, intellectual property portfolios and compliance with stringent regulatory standards (such as ISO and FDA for medical lasers) further consolidate the positions of leading manufacturers.

- Key competitive factors include wavelength precision, system uptime, after-sales service, and integration with advanced manufacturing systems.

- Market leaders are increasingly investing in AI-driven diagnostics and remote monitoring to enhance product value and customer retention.

- Barriers to entry remain high due to capital intensity, technical complexity, and the need for long-term customer relationships.

Overall, the xenon-based excimer laser manufacturing sector in 2025 is marked by technological leadership, global supply chain integration, and a focus on high-growth end-use applications, with established players maintaining dominance while new entrants seek to disrupt through innovation and regional expansion.

Market Growth Forecasts (2025–2030): CAGR, Revenue, and Volume Analysis

The xenon-based excimer laser manufacturing market is poised for robust growth between 2025 and 2030, driven by expanding applications in semiconductor lithography, ophthalmology, and advanced materials processing. According to projections from MarketsandMarkets, the global excimer laser market, with xenon-based systems comprising a significant share, is expected to register a compound annual growth rate (CAGR) of approximately 7.2% during this period. This growth is underpinned by the increasing demand for high-precision photolithography in semiconductor manufacturing, where xenon-based excimer lasers are critical for producing advanced integrated circuits at sub-10nm nodes.

Revenue forecasts indicate that the xenon-based excimer laser segment will reach an estimated market value of USD 1.8 billion by 2030, up from around USD 1.1 billion in 2025. This surge is attributed to the ongoing investments in next-generation chip fabrication facilities by leading foundries such as TSMC and Samsung Electronics, both of which rely on excimer laser technology for extreme ultraviolet (EUV) and deep ultraviolet (DUV) lithography processes.

In terms of volume, the annual shipment of xenon-based excimer laser units is projected to grow from approximately 2,500 units in 2025 to over 3,800 units by 2030. This increase is fueled by the proliferation of laser-based eye surgeries, such as LASIK and photorefractive keratectomy (PRK), where xenon-based excimer lasers are preferred for their precision and minimal thermal damage. The medical device sector, led by companies like Alcon and Carl Zeiss Meditec, is expected to account for a growing share of unit demand, particularly in emerging markets across Asia-Pacific and Latin America.

Regionally, Asia-Pacific is forecasted to dominate both revenue and volume growth, supported by aggressive semiconductor industry expansion and increasing healthcare infrastructure investments. North America and Europe will continue to represent mature markets, with steady replacement demand and incremental adoption in research and industrial applications. Overall, the 2025–2030 period will see xenon-based excimer laser manufacturing benefit from technological advancements, rising end-user demand, and strategic capacity expansions by key industry players.

Regional Market Analysis: North America, Europe, Asia-Pacific, and Rest of World

The global xenon-based excimer laser manufacturing market demonstrates distinct regional dynamics, shaped by technological innovation, regulatory environments, and end-user demand across North America, Europe, Asia-Pacific, and the Rest of the World (RoW).

North America remains a leading region, driven by robust investments in semiconductor manufacturing, medical device innovation, and advanced research infrastructure. The United States, in particular, benefits from the presence of major industry players and a strong focus on R&D, especially in photolithography and ophthalmic applications. The region’s market growth is further supported by government initiatives to bolster domestic semiconductor production, as seen in the CHIPS Act, which is expected to stimulate demand for high-precision excimer lasers in 2025. According to SEMI, North American equipment manufacturers are projected to see continued growth in laser system orders, with xenon-based excimer lasers playing a critical role in next-generation chip fabrication.

Europe is characterized by a strong emphasis on quality standards and regulatory compliance, particularly in medical and industrial laser applications. Germany, the Netherlands, and France are key contributors, with established photonics clusters and collaborations between academia and industry. The European Union’s focus on technological sovereignty and investments in microelectronics, as outlined in the European Chips Act, are expected to drive further adoption of xenon-based excimer lasers in 2025. Photonics21 reports that European manufacturers are increasingly integrating excimer lasers into advanced manufacturing and medical device production, supporting regional market expansion.

- Asia-Pacific is the fastest-growing region, propelled by aggressive investments in semiconductor fabrication, display manufacturing, and medical technology. China, Japan, South Korea, and Taiwan are at the forefront, with government-backed initiatives to localize high-value manufacturing and reduce reliance on imports. The region’s rapid adoption of EUV lithography and flat-panel display production is fueling demand for xenon-based excimer lasers. According to SEMI, Asia-Pacific accounted for over 60% of global semiconductor equipment spending in 2024, a trend expected to continue into 2025.

- Rest of World (RoW) markets, including Latin America, the Middle East, and Africa, are emerging as niche adopters, primarily in medical and research applications. While market size remains modest, increasing healthcare investments and technology transfer initiatives are expected to gradually boost demand for xenon-based excimer lasers in these regions.

Overall, regional market trajectories in 2025 will be shaped by the interplay of technological leadership, policy support, and end-user industry growth, with Asia-Pacific and North America leading in volume and innovation, and Europe maintaining a stronghold in quality-driven applications.

Challenges and Opportunities in Xenon-Based Excimer Laser Manufacturing

The manufacturing of xenon-based excimer lasers in 2025 faces a dynamic landscape shaped by both persistent challenges and emerging opportunities. As these lasers are critical for applications in semiconductor lithography, ophthalmology, and materials processing, manufacturers must navigate complex technical, economic, and supply chain factors to remain competitive.

One of the primary challenges is the stringent purity requirements for xenon gas and other halogen components. Even trace impurities can significantly degrade laser performance and lifespan, necessitating advanced purification and quality control systems. This increases production costs and requires close collaboration with specialty gas suppliers such as Air Liquide and Linde plc. Additionally, the global supply of xenon is subject to volatility due to its byproduct status in air separation units, leading to price fluctuations and potential shortages, as highlighted in recent reports by S&P Global (IHS Markit).

Technical complexity is another hurdle. The precision required in assembling excimer laser systems—particularly in aligning optical components and managing high-voltage power supplies—demands skilled labor and sophisticated manufacturing environments. This can limit scalability and increase lead times, especially as demand for advanced lithography tools grows in the semiconductor sector (ASML Holding).

Despite these challenges, several opportunities are driving innovation and growth. The ongoing miniaturization of semiconductor devices is fueling demand for high-performance excimer lasers, particularly in deep ultraviolet (DUV) lithography. This trend is prompting investments in R&D to improve laser efficiency, reliability, and operational lifespans. Companies like Coherent Corp. and Cymer (ASML) are developing next-generation systems with enhanced pulse stability and lower maintenance requirements.

Furthermore, the push for sustainability is encouraging the adoption of recycling and recovery technologies for xenon gas, potentially mitigating supply risks and reducing environmental impact. Strategic partnerships between laser manufacturers and gas suppliers are also emerging as a way to secure long-term xenon contracts and stabilize costs.

In summary, while xenon-based excimer laser manufacturing in 2025 is challenged by supply chain volatility, technical demands, and cost pressures, it is also positioned to benefit from technological advancements, growing end-market demand, and evolving supply strategies. The sector’s ability to innovate and adapt will be crucial for capitalizing on these opportunities in the coming years.

Future Outlook: Innovation, Investment, and Emerging Applications

The future outlook for xenon-based excimer laser manufacturing in 2025 is shaped by a convergence of technological innovation, increased investment, and the emergence of new application domains. As the demand for high-precision laser systems intensifies across industries such as semiconductor manufacturing, ophthalmology, and advanced materials processing, manufacturers are prioritizing research and development to enhance the performance, efficiency, and reliability of xenon-based excimer lasers.

Innovation is expected to focus on improving pulse stability, beam homogeneity, and operational lifespans. Leading manufacturers are investing in advanced gas handling systems, real-time monitoring, and automated calibration to reduce downtime and maintenance costs. These advancements are particularly critical for the semiconductor industry, where xenon-based excimer lasers are integral to photolithography processes at sub-10nm nodes. The transition to extreme ultraviolet (EUV) lithography is also driving the need for more robust and efficient excimer laser sources, prompting collaborations between laser manufacturers and chipmakers such as ASML and Intel.

Investment trends indicate a growing influx of capital from both established players and venture-backed startups. According to MarketsandMarkets, the global excimer laser market is projected to grow at a CAGR of over 6% through 2025, with xenon-based systems accounting for a significant share due to their versatility and established use cases. Strategic partnerships and mergers are also anticipated, as companies seek to expand their technological capabilities and global reach.

Emerging applications are broadening the addressable market for xenon-based excimer lasers. In medical technology, new frontiers in corneal surgery, dermatology, and tissue engineering are being explored, leveraging the precision and minimal thermal damage offered by these lasers. In materials science, xenon-based excimer lasers are enabling novel surface treatments, microstructuring, and the fabrication of flexible electronics. Additionally, the rise of quantum computing and advanced display manufacturing presents new opportunities for tailored excimer laser solutions.

- Continued R&D to enhance laser stability and efficiency

- Increased investment from both industry leaders and new entrants

- Expansion into medical, materials, and quantum technology applications

- Strategic collaborations to address evolving semiconductor requirements

Overall, 2025 is poised to be a pivotal year for xenon-based excimer laser manufacturing, with innovation and investment driving the sector toward broader adoption and new technological frontiers.

Sources & References

- MarketsandMarkets

- Coherent Corp.

- Nikon Corporation

- Linde

- ZEISS

- ASML

- USHIO Inc.

- Jenoptik AG

- Gigaphoton Inc.

- Alcon

- Photonics21

- Air Liquide